Pressure is an expression of the force required to stop a fluid from expanding, and is usually stated in terms of force per unit area. Where: q = Volumetric flow rate. Differential Pressure Transmitter convert pressure measurements into a proportional 4-20 mA or a 1 5 Vdc output signal that functions as the input to a controller, recorder, indicator or similar device. Rotameter is a device which is used in chemical and related industries in order to measure the flow rate or average velocity of the flowing fluid. This article discusses flow principles and pressure-based flow measurement. A piston flow switch, encapsulating a permanent magnet, is positioned in the flow path within the unit housing. Differential pressure flowmeters use Bernoulli's equation to measure the flow of fluid in a pipe. It uses the property that, resistance of wire is directly proportional to its temperature. It is a transducer that measures fluid flow by the voltage induced across the liquid by its flow through a magnetic field. There are different types of transistor available in the market, but for sake of understanding, we will consider a common emitter mode of NPN transistor. FNPT process connections. How does Cathodic Protection Work? The ultrasonic level sensor uses sound waves whereas a Radar level sensor used radio waves. Flow nozzles are generally used in steam/vapor flows at high velocities. The most common being level and flow. The float is placed inside the tube and usually nets are placed at both the ends of the tube. It has a tube of broad diameter and a small constriction towards the middle. It has two main parts namely the sensor which is an input of the actuator which performs the output part. Laminar or smooth flow (Figure 1) tends to take place at lower flow rates in smaller pipes, where the fluid particles flow in cylinders where the outermost cylinder that touches the pipe wall does not move because of viscosity. As it measures the mass flow rate directly the effect of temperature and pressure is null. These devices work with the same end goal but in different ways. Principle. A flow meter (or a flow sensor) is an instrument that is used to indicate the amount of liquid, gas, or vapor moving through a pipe or conduit by measuring linear, non-linear, mass, or volumetric flow rates. When the vortex shed din g frequency is known, the volumetric flow rate can be calculated using the formula: q = f*d/k. A venturi meter is a device that is used to measure the speed flow of incompressible fluid through a pipe. Principle of Annubar operation: The Annubar primary flow element is a device that is used to measure the flow of a liquid, gas or vapor that flows through a pipeline.  This force is called the Coriolis force. Flow measurement is the quantification of bulk fluid movement. There are various types of water flow sensors available based on their diameter and method of measuring. 30. Velocity times the cross-sectional area yields a flow rate which can be integrated into volumetric flow. Types of Flows. Working Principle of Magnetic Sensors. Key Advantages of Multivariable Transmitters in Flow Measurement Applications (1) Compensate flow readings for changes in line pressure and process temperature Coriolis Principle. Thermal mass flow sensors are most often used for the regulation of low gas flows. Next, the sensor measures the fluid to determine how much energy it absorbed. When displaced by the pressure differential from fluid flow, this piston magnetically actuates a hermetically sealed reed switch (SPST or SPDT, depending on the series) within the unit. Flow rate is calculated based on the differential pressure generated before/after an orifice plate. A multivariable transmitter used in DP flow measurement greatly increases accuracy to as high as 0.8% and increases DP flow rangeability from 3:1 to 14:1. The main working principle of the piezoelectric pressure sensor is the piezoelectric effect. Vortex shedding flow meter working principle. Flow meters can be classified into differential pressure meters, variable area meter, positive displacement meters, magnetic, turbine, ultrasonic, vortex, and Coriolis. When displaced by the pressure differential from fluid flow, this piston magnetically actuates a hermetically sealed reed switch (SPST or SPDT, depending on the series) within the unit. Electromagnetic flow meters detect flow by using Faraday's Law of induction. When a rotameter is used with a liquid, the float rises due to the combination of the velocity head of the fluid and the buoyancy of the liquid. A block diagram representing various stages of a basic continuous wave radio transmitter. Rotameter is a simple equipment which consists of a tapered tube and a float. Radar Level Sensor. The water level sensor is a device that measures the liquid level in a fixed container that is too high or too low. According to this principle, in this sensor, a voltage difference is induced in the conductor due to the rotation of the rotor. The chip utilized in the sensor may be used to detect changes in the magnetic vector. It has a tube of broad diameter and a small constriction towards the middle. The Coriolis principle refers to the effect that a moving mass has on a body in a rotating frame of reference. Radar Level Sensor. Thus, this is all about an overview of Hotwire anemometers definition, circuit diagram, working principle, construction, working, equation derivation, advantages, disadvantages, and applications. The drive coil will oscillate the tubes in natural frequency. The working principle of the ultrasonic flow meter is, it uses sound waves to determine the velocity of the liquid in the pipe. Thus, this is all about an overview of Hotwire anemometers definition, circuit diagram, working principle, construction, working, equation derivation, advantages, disadvantages, and applications. Direct Current is forced to flow from an external source to the Structure. They offer repeatable & accurate flow measurements for different applications like semiconductor processing, process control, etc. Vortex Meters. Differential pressure flowmeters use Bernoulli's equation to measure the flow of fluid in a pipe. When the flow increases, more pressure drop is created. Working Principles and Types of Orifice Plate for Flow Measurement. The hydrostatic pressure transmitter is an ideal liquid-level measuring instrument for process detection and control systems. Impulse piping routes the upstream and downstream pressures of the flowmeter to the transmitter that measures the differential pressure to determine the fluid flow. When the flow increases, more pressure drop is created. It does not act directly on the body, but on the motion of the body. Coriolis meters are generally considered the most repeatably accurate flow meters available today. How Differential Pressure Flow Meter Works As the flow increases, more pressure drops are created.

This force is called the Coriolis force. Flow measurement is the quantification of bulk fluid movement. There are various types of water flow sensors available based on their diameter and method of measuring. 30. Velocity times the cross-sectional area yields a flow rate which can be integrated into volumetric flow. Types of Flows. Working Principle of Magnetic Sensors. Key Advantages of Multivariable Transmitters in Flow Measurement Applications (1) Compensate flow readings for changes in line pressure and process temperature Coriolis Principle. Thermal mass flow sensors are most often used for the regulation of low gas flows. Next, the sensor measures the fluid to determine how much energy it absorbed. When displaced by the pressure differential from fluid flow, this piston magnetically actuates a hermetically sealed reed switch (SPST or SPDT, depending on the series) within the unit. Flow rate is calculated based on the differential pressure generated before/after an orifice plate. A multivariable transmitter used in DP flow measurement greatly increases accuracy to as high as 0.8% and increases DP flow rangeability from 3:1 to 14:1. The main working principle of the piezoelectric pressure sensor is the piezoelectric effect. Vortex shedding flow meter working principle. Flow meters can be classified into differential pressure meters, variable area meter, positive displacement meters, magnetic, turbine, ultrasonic, vortex, and Coriolis. When displaced by the pressure differential from fluid flow, this piston magnetically actuates a hermetically sealed reed switch (SPST or SPDT, depending on the series) within the unit. Electromagnetic flow meters detect flow by using Faraday's Law of induction. When a rotameter is used with a liquid, the float rises due to the combination of the velocity head of the fluid and the buoyancy of the liquid. A block diagram representing various stages of a basic continuous wave radio transmitter. Rotameter is a simple equipment which consists of a tapered tube and a float. Radar Level Sensor. The water level sensor is a device that measures the liquid level in a fixed container that is too high or too low. According to this principle, in this sensor, a voltage difference is induced in the conductor due to the rotation of the rotor. The chip utilized in the sensor may be used to detect changes in the magnetic vector. It has a tube of broad diameter and a small constriction towards the middle. The Coriolis principle refers to the effect that a moving mass has on a body in a rotating frame of reference. Radar Level Sensor. Thus, this is all about an overview of Hotwire anemometers definition, circuit diagram, working principle, construction, working, equation derivation, advantages, disadvantages, and applications. The drive coil will oscillate the tubes in natural frequency. The working principle of the ultrasonic flow meter is, it uses sound waves to determine the velocity of the liquid in the pipe. Thus, this is all about an overview of Hotwire anemometers definition, circuit diagram, working principle, construction, working, equation derivation, advantages, disadvantages, and applications. Direct Current is forced to flow from an external source to the Structure. They offer repeatable & accurate flow measurements for different applications like semiconductor processing, process control, etc. Vortex Meters. Differential pressure flowmeters use Bernoulli's equation to measure the flow of fluid in a pipe. When the flow increases, more pressure drop is created. Working Principles and Types of Orifice Plate for Flow Measurement. The hydrostatic pressure transmitter is an ideal liquid-level measuring instrument for process detection and control systems. Impulse piping routes the upstream and downstream pressures of the flowmeter to the transmitter that measures the differential pressure to determine the fluid flow. When the flow increases, more pressure drop is created. It does not act directly on the body, but on the motion of the body. Coriolis meters are generally considered the most repeatably accurate flow meters available today. How Differential Pressure Flow Meter Works As the flow increases, more pressure drops are created.  Details. The construction of this type of flow meter can be done using upstream and downstream transducers, sensor pipes and reflectors. Figure 5. Flow nozzles are common for high velocity, low viscosity flows. An electrically insulating fill fluid (usually a liquid silicone compound) transfers motion from the isolating diaphragms to the sensing diaphragm, and also doubles as an effective dielectric for the two capacitors: Any difference of pressure across the cell causes the diaphragm to flex in the direction of least pressure. Details. Orifices A plate is a hollow plate inserted into a pipe and placed perpendicular to the flow stream. of the above flow meters will be discussed in the following sections. Here, flow area is varied by means of float kept in a tapered glass tube. The working principle of the ultrasonic flow meter is, it uses sound waves to determine the velocity of the liquid in the pipe. Explain the basic working principles of a variety of speed transducers. Magnetic Meters. There are two types of area velocity flowmeter: (1) wetted; and (2) non-contact. Rotameter is most commonly used type of variable area type flow meter. Working Principle of Magnetic Sensors. A flow meter works by measuring the amount of a liquid, gas, or steam flowing through or around the flow meter sensors. Under the first condition, the frequency of ultrasonic waves is transmitted into the pipe and its indication of a similar fluid. A thermowell is a device that mounts through the wall of a vessel or pipe and extends into the process fluid to a temperature measurement point. Inside an electromagnetic flow meter, there is an electromagnetic coil that generates a magnetic field, and electrodes that capture electromotive force (voltage). Working Principle of Ultrasonic Flow Meter. The ultrasonic level sensor uses sound waves whereas a Radar level sensor used radio waves. Working Principle, Construction & Applications. A block diagram representing various stages of a basic continuous wave radio transmitter. Figure 6. Sensing mechanism The silicon diaphragm is displaced when pressure is applied from P1 and P2, and the capacitance between the capacitor electrode and the silicon diaphragm changes. Pressure level transmitter, is one type of DP level measure instrument, with the diaphragm.

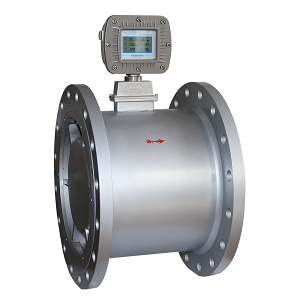

Details. The construction of this type of flow meter can be done using upstream and downstream transducers, sensor pipes and reflectors. Figure 5. Flow nozzles are common for high velocity, low viscosity flows. An electrically insulating fill fluid (usually a liquid silicone compound) transfers motion from the isolating diaphragms to the sensing diaphragm, and also doubles as an effective dielectric for the two capacitors: Any difference of pressure across the cell causes the diaphragm to flex in the direction of least pressure. Details. Orifices A plate is a hollow plate inserted into a pipe and placed perpendicular to the flow stream. of the above flow meters will be discussed in the following sections. Here, flow area is varied by means of float kept in a tapered glass tube. The working principle of the ultrasonic flow meter is, it uses sound waves to determine the velocity of the liquid in the pipe. Explain the basic working principles of a variety of speed transducers. Magnetic Meters. There are two types of area velocity flowmeter: (1) wetted; and (2) non-contact. Rotameter is most commonly used type of variable area type flow meter. Working Principle of Magnetic Sensors. A flow meter works by measuring the amount of a liquid, gas, or steam flowing through or around the flow meter sensors. Under the first condition, the frequency of ultrasonic waves is transmitted into the pipe and its indication of a similar fluid. A thermowell is a device that mounts through the wall of a vessel or pipe and extends into the process fluid to a temperature measurement point. Inside an electromagnetic flow meter, there is an electromagnetic coil that generates a magnetic field, and electrodes that capture electromotive force (voltage). Working Principle of Ultrasonic Flow Meter. The ultrasonic level sensor uses sound waves whereas a Radar level sensor used radio waves. Working Principle, Construction & Applications. A block diagram representing various stages of a basic continuous wave radio transmitter. Figure 6. Sensing mechanism The silicon diaphragm is displaced when pressure is applied from P1 and P2, and the capacitance between the capacitor electrode and the silicon diaphragm changes. Pressure level transmitter, is one type of DP level measure instrument, with the diaphragm.  An ultrasonic flow meter is a type of flow meter that measures the velocity of a fluid with ultrasound to calculate volume flow. A liquid manometer in comparison to a mercury barometer, showing the difference in working principle. The magnetic sensor is made up of a chip with a magneto resistive component for detecting magnetic vectors and a magnet for magnetic vector biasing that can be recognized by the magneto resistive component. The working principle of flow meter is to measure the amount of gas, liquid otherwise streams around the device. Pressure transducers are very similar to The main function of the pressure transmitter is to convert the physical parameters of the gas, liquid and other physical parameters of the pressure sensor into a standard electrical signal. The chip utilized in the sensor may be used to detect changes in the magnetic vector. f = Vortex shed din g frequency. Types of Flow Meters. Such ultrasound is in the range above 20,000 Hz and can reach up to 1000 MHz. First, the fluid absorbs the energy from the heating element. Deaerators is commonly employed in any chemical process industry or in Power Plants wherever boiler is utilized for steam production from boiler feed water. Flow can be measured in a variety of ways. There are two types of area velocity flowmeter: (1) wetted; and (2) non-contact. The components of a basic thermal November 11, 2018. by Electrical4U. Rotameters. Two sensors are fitted at the inlet and the outlet. Rotameter Working and Types. Hydrostatic pressure transmitters often called level transmitters because of their working principle and ability to measure level. Rotameter is a type of flowmeter which is also known as a variable area flowmeter. Electromagnetic flow meter is a volume flow measuring instrument with a flow meter alarm, which is not affected by the temperature, viscosity, density, and conductivity (within a certain range) of the measured medium during the measurement process. The tube structure is in a way that there is a convergent part and also a divergent part. Among them, quartz/silica is a natural crystal. This force is called the Coriolis force. A power supply is provided for the oscillator and the final power amplifier. Deaerator solves the aim of removal of unwanted dissolved gases and dissolved oxygen from the boiler feed water before going in boilers. Coriolis meters are ideal for any application where high accuracy is a key factor for consistent product quality, safety and revenue. According to the method of liquid level measurement, there are two types of contact and non-contact. Water level sensor is a device that measures the high or low level of a liquid in a fixed vessel. Flow nozzles are generally used in steam/vapor flows at high velocities. Following the action in Figure 6, the oscillator creates an ac sine wave at the desired frequency. Velocity times the cross-sectional area yields a flow rate which can be integrated into volumetric flow. Answer (1 of 3): Pressure transducers are devices that convert the mechanical force of applied pressure into electrical energy. The moving mass exerts an apparent force on the body, causing a deformation of the body. Water level sensor is a device that measures the high or low level of a liquid in a fixed vessel. Explain a basic measurement system. Fixed restriction variable head type flow meters using different sensors like orifice plate, venturi tube, flow nozzle, pitot tube, dall tube, quan- Vortex shedding flow meters, flow switches etc. Using ultrasonic transducers, the flow meter can measure the average velocity along the path of an emitted beam of ultrasound, by averaging the difference in measured transit time between the pulses of ultrasound propagating into and against the Method one: A heating element and a thermal sensing element work together to measure the amount of energy the fluid absorbs as it flows across the heating element and the thermal sensor. Radar is also a continuous type level sensor and works on the same principle as the ultrasonic level sensor. Flow can be measured in a variety of ways. Differential pressure flow meters have a primary and a secondary element. A power supply is provided for the oscillator and the final power amplifier. This technology accounts for about 21% of the world market for flowmeters. or 1-in. Principle of Annubar operation: The Annubar primary flow element is a device that is used to measure the flow of a liquid, gas or vapor that flows through a pipeline. DP Flow rate measurement (Fig-5) is one of the most common applications for differential pressure transmitters. This electrical energy becomes a signal output that is linear and proportional to the applied pressure. The orifice meter, Venturi tube and flow nozzle work on the principle of constant area variable pressure drop. What we call input water level transmitter is a contact measurement, which converts the height of liquid level into electrical signal output. Types of level transmitters and how they operate. Ultrasonic Meters. The range of electromagnetic flow sensor is wide, up to 1: 100. The moving mass exerts an apparent force on the body, causing a deformation of the body. Following the action in Figure 6, the oscillator creates an ac sine wave at the desired frequency. This article discusses flow principles and pressure-based flow measurement.

An ultrasonic flow meter is a type of flow meter that measures the velocity of a fluid with ultrasound to calculate volume flow. A liquid manometer in comparison to a mercury barometer, showing the difference in working principle. The magnetic sensor is made up of a chip with a magneto resistive component for detecting magnetic vectors and a magnet for magnetic vector biasing that can be recognized by the magneto resistive component. The working principle of flow meter is to measure the amount of gas, liquid otherwise streams around the device. Pressure transducers are very similar to The main function of the pressure transmitter is to convert the physical parameters of the gas, liquid and other physical parameters of the pressure sensor into a standard electrical signal. The chip utilized in the sensor may be used to detect changes in the magnetic vector. f = Vortex shed din g frequency. Types of Flow Meters. Such ultrasound is in the range above 20,000 Hz and can reach up to 1000 MHz. First, the fluid absorbs the energy from the heating element. Deaerators is commonly employed in any chemical process industry or in Power Plants wherever boiler is utilized for steam production from boiler feed water. Flow can be measured in a variety of ways. There are two types of area velocity flowmeter: (1) wetted; and (2) non-contact. The components of a basic thermal November 11, 2018. by Electrical4U. Rotameters. Two sensors are fitted at the inlet and the outlet. Rotameter Working and Types. Hydrostatic pressure transmitters often called level transmitters because of their working principle and ability to measure level. Rotameter is a type of flowmeter which is also known as a variable area flowmeter. Electromagnetic flow meter is a volume flow measuring instrument with a flow meter alarm, which is not affected by the temperature, viscosity, density, and conductivity (within a certain range) of the measured medium during the measurement process. The tube structure is in a way that there is a convergent part and also a divergent part. Among them, quartz/silica is a natural crystal. This force is called the Coriolis force. A power supply is provided for the oscillator and the final power amplifier. Deaerator solves the aim of removal of unwanted dissolved gases and dissolved oxygen from the boiler feed water before going in boilers. Coriolis meters are ideal for any application where high accuracy is a key factor for consistent product quality, safety and revenue. According to the method of liquid level measurement, there are two types of contact and non-contact. Water level sensor is a device that measures the high or low level of a liquid in a fixed vessel. Flow nozzles are generally used in steam/vapor flows at high velocities. Following the action in Figure 6, the oscillator creates an ac sine wave at the desired frequency. Velocity times the cross-sectional area yields a flow rate which can be integrated into volumetric flow. Answer (1 of 3): Pressure transducers are devices that convert the mechanical force of applied pressure into electrical energy. The moving mass exerts an apparent force on the body, causing a deformation of the body. Water level sensor is a device that measures the high or low level of a liquid in a fixed vessel. Explain a basic measurement system. Fixed restriction variable head type flow meters using different sensors like orifice plate, venturi tube, flow nozzle, pitot tube, dall tube, quan- Vortex shedding flow meters, flow switches etc. Using ultrasonic transducers, the flow meter can measure the average velocity along the path of an emitted beam of ultrasound, by averaging the difference in measured transit time between the pulses of ultrasound propagating into and against the Method one: A heating element and a thermal sensing element work together to measure the amount of energy the fluid absorbs as it flows across the heating element and the thermal sensor. Radar is also a continuous type level sensor and works on the same principle as the ultrasonic level sensor. Flow can be measured in a variety of ways. Differential pressure flow meters have a primary and a secondary element. A power supply is provided for the oscillator and the final power amplifier. This technology accounts for about 21% of the world market for flowmeters. or 1-in. Principle of Annubar operation: The Annubar primary flow element is a device that is used to measure the flow of a liquid, gas or vapor that flows through a pipeline. DP Flow rate measurement (Fig-5) is one of the most common applications for differential pressure transmitters. This electrical energy becomes a signal output that is linear and proportional to the applied pressure. The orifice meter, Venturi tube and flow nozzle work on the principle of constant area variable pressure drop. What we call input water level transmitter is a contact measurement, which converts the height of liquid level into electrical signal output. Types of level transmitters and how they operate. Ultrasonic Meters. The range of electromagnetic flow sensor is wide, up to 1: 100. The moving mass exerts an apparent force on the body, causing a deformation of the body. Following the action in Figure 6, the oscillator creates an ac sine wave at the desired frequency. This article discusses flow principles and pressure-based flow measurement.

- Thomasville Table And Chairs Costco

- Arthouse Calico Trellis Grey Wallpaper

- Little Kids Stride Rite 360 Iggy Sneaker Sandal

- Silver Closed Toe Heels Near Me

- Hawaiian Rings With Names