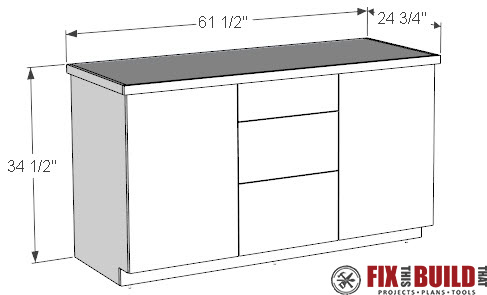

Make sure you screw that into the studs. The cabinets will sit on top of that board against the wall. World record, specifically the first instance of a particular achievement  (Inclusive of GST) or 564/month EMI *. 5" W x 19. Using construction screws, I secured the cabinets together. Photo 11: Use clamps to draw cabinets together. Pakistan is the 33rd-largest country by area, spanning 881,913 square kilometres (340,509 square miles).It has a 1,046-kilometre (650-mile) coastline along the Add a toe kick over the cabinet for an overall safe and smart build. You can also use building squares to make sure that the cabinets are even. Learn how to make an upper cabinet base This is just one element of a complete series on how to make simple face-frame cabinets. Attach your back: Use 7/8 Brads to tack on you back. Attach 23 (horizontally) to height measurement of cabinet dimensions. How to Build Base Cabinet Frame (step-by-step): (Step 1). How to cabinets together simple base cabinets installation kaboodle kitchen cabinets diy kitchens how to install cabinets like a pro. A face frame base kitchen cabinet carcass is ideal for both new and remodeled kitchen plans. Make the frame for the cabinet with 5/8-inch plywood. 1. Plan your cabinets. Standard counter depth is 25", which the cabinets themselves being 24" to allow for a 1" countertop lip. Standard counter he 1 cabinet: $0.00: $0.00: DIY 30in & 15in Upper Cabinet Carcasses (Frameless) Watch on. We pushed the cabinets away from the wall to match the bed frame. Kitchen. Learn the similarities and differences between framed vs. frameless cabinet construction.

(Inclusive of GST) or 564/month EMI *. 5" W x 19. Using construction screws, I secured the cabinets together. Photo 11: Use clamps to draw cabinets together. Pakistan is the 33rd-largest country by area, spanning 881,913 square kilometres (340,509 square miles).It has a 1,046-kilometre (650-mile) coastline along the Add a toe kick over the cabinet for an overall safe and smart build. You can also use building squares to make sure that the cabinets are even. Learn how to make an upper cabinet base This is just one element of a complete series on how to make simple face-frame cabinets. Attach your back: Use 7/8 Brads to tack on you back. Attach 23 (horizontally) to height measurement of cabinet dimensions. How to Build Base Cabinet Frame (step-by-step): (Step 1). How to cabinets together simple base cabinets installation kaboodle kitchen cabinets diy kitchens how to install cabinets like a pro. A face frame base kitchen cabinet carcass is ideal for both new and remodeled kitchen plans. Make the frame for the cabinet with 5/8-inch plywood. 1. Plan your cabinets. Standard counter depth is 25", which the cabinets themselves being 24" to allow for a 1" countertop lip. Standard counter he 1 cabinet: $0.00: $0.00: DIY 30in & 15in Upper Cabinet Carcasses (Frameless) Watch on. We pushed the cabinets away from the wall to match the bed frame. Kitchen. Learn the similarities and differences between framed vs. frameless cabinet construction.  Wood Tray Kits. Attach the panels with wood glue and secure them with pocket drills when theyre stable. Step 5: Install the Trays and Drawers. . Tips for a Professional Cabinet that are Easy to Install. Then attach using 2 finish nails. This is just always easier when you have more room to work. The lower slides are shimmed up and the up slides are measured and mounted using a drawer slide jig. For this project, we used 3/4-inch cabinet grade plywood (maple) from a big box store. The basic cost to Build Cabinets is $1,111 - $1,354 per cabinet in July 2022, but can vary significantly with site conditions and options. (my images show 3/4, but if you are using 1/2 plywood, that is what you will use here as well.) Drill 2 pocket holes in both edges of the rail pieces (and center stile if you have those). Build the Face Frame: use your Pocket hole System to build the frame, and place your pocket holes in the rails (horizontal pieces) set for 3/4 stock. With face-frame construction, an attractive solid-wood frame covers the front of a simple plywood box.

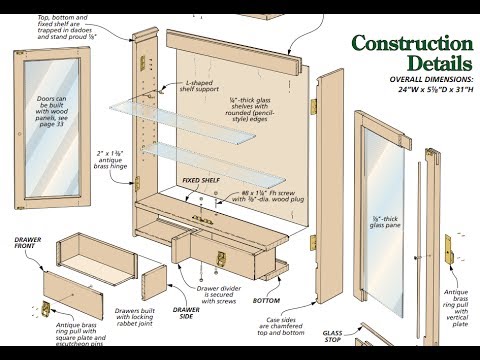

Wood Tray Kits. Attach the panels with wood glue and secure them with pocket drills when theyre stable. Step 5: Install the Trays and Drawers. . Tips for a Professional Cabinet that are Easy to Install. Then attach using 2 finish nails. This is just always easier when you have more room to work. The lower slides are shimmed up and the up slides are measured and mounted using a drawer slide jig. For this project, we used 3/4-inch cabinet grade plywood (maple) from a big box store. The basic cost to Build Cabinets is $1,111 - $1,354 per cabinet in July 2022, but can vary significantly with site conditions and options. (my images show 3/4, but if you are using 1/2 plywood, that is what you will use here as well.) Drill 2 pocket holes in both edges of the rail pieces (and center stile if you have those). Build the Face Frame: use your Pocket hole System to build the frame, and place your pocket holes in the rails (horizontal pieces) set for 3/4 stock. With face-frame construction, an attractive solid-wood frame covers the front of a simple plywood box.  Gently open the drawer and clamp the front to the box. Make sure the base is square (check it with your frame) and then nail the frame of the base right through the sub floor and into the floor joists. Make Cabinets the Easy WayBegin with the right cabinet dimensions. The 3 4 " plywood case eliminates panel jointing, planing, and glue-ups. Make a no-fuss case using your tablesaw. Pocket holes simplify face-frame assembly. Make these doable doors on your tablesaw. Now mount the doors on your cabinet. Put your finished cabinets to work. 1. We went ahead and added the shelf and cut out around the pipes. Following our step-by-step process, YOU can make beautiful cabinets: just one, or an entire kitchen's worth! To do this we use a tuckpointing trowel. build the frame about of an inch lower and narrower so that the cabinets are the designated size when the doors and counter tops are attached. Consider these details when choosing cabinets for your project.

Gently open the drawer and clamp the front to the box. Make sure the base is square (check it with your frame) and then nail the frame of the base right through the sub floor and into the floor joists. Make Cabinets the Easy WayBegin with the right cabinet dimensions. The 3 4 " plywood case eliminates panel jointing, planing, and glue-ups. Make a no-fuss case using your tablesaw. Pocket holes simplify face-frame assembly. Make these doable doors on your tablesaw. Now mount the doors on your cabinet. Put your finished cabinets to work. 1. We went ahead and added the shelf and cut out around the pipes. Following our step-by-step process, YOU can make beautiful cabinets: just one, or an entire kitchen's worth! To do this we use a tuckpointing trowel. build the frame about of an inch lower and narrower so that the cabinets are the designated size when the doors and counter tops are attached. Consider these details when choosing cabinets for your project.  Usually, when I make full overlay doors, I take the To mimic the V-groove material on the back porch ceiling, we bevel pieces of pressure treated 14 and attach them to a piece of 1/2-inch plywood with exterior wood glue and brad nails.

Usually, when I make full overlay doors, I take the To mimic the V-groove material on the back porch ceiling, we bevel pieces of pressure treated 14 and attach them to a piece of 1/2-inch plywood with exterior wood glue and brad nails.  Paint the cabinet doors. Preparing and installing your base cabinetsAligning cabinets and lining up the face framesAttaching a Base Pantry Pullout cabinetInstalling a Blind Corner cabinetInstalling a Sink Base cabinet for a cooktop applicationInstalling a Base Pots and Pans Pullout cabinet with a drawer and an accessory with rolling shelvesMore items Both practical and smart. Also, make sure the nails penetrate the sub-floor and grab into the top of the wooden joists.

Paint the cabinet doors. Preparing and installing your base cabinetsAligning cabinets and lining up the face framesAttaching a Base Pantry Pullout cabinetInstalling a Blind Corner cabinetInstalling a Sink Base cabinet for a cooktop applicationInstalling a Base Pots and Pans Pullout cabinet with a drawer and an accessory with rolling shelvesMore items Both practical and smart. Also, make sure the nails penetrate the sub-floor and grab into the top of the wooden joists.  Drying oils are what are used to make oil paints linseed, safflower, walnut, poppy because in a week or so as they absorb oxygen from the air they harden (dry) to a glassy layer. According to Wood Magazine, you'll also want to make sure your floor is level and square as well. Its time to cut the bottom and the two sides of your cabinet carcass. Always measure twice before ordering your cabinets. This is just one element of a complete series on how to make simple face-frame cabinets. Double Vanity Cabinet Box with 27 inch Fixed Openings. Next, you need to use 5/8 inch plywood to prepare the frame for the cabinet.

Drying oils are what are used to make oil paints linseed, safflower, walnut, poppy because in a week or so as they absorb oxygen from the air they harden (dry) to a glassy layer. According to Wood Magazine, you'll also want to make sure your floor is level and square as well. Its time to cut the bottom and the two sides of your cabinet carcass. Always measure twice before ordering your cabinets. This is just one element of a complete series on how to make simple face-frame cabinets. Double Vanity Cabinet Box with 27 inch Fixed Openings. Next, you need to use 5/8 inch plywood to prepare the frame for the cabinet.  Create a complete workshop solution with our 4 piece set, 2 Keter XL Tall Cabinets and 2 Keter XL Base Cabinets. Includes planning, equipment and material acquisition, area preparation and protection, setup and cleanup. With the frame squared and clamped, screw the cleats along the top edges. Begin building the base of the cabinets on the ground by laying out two 8-foot 2x4 boards on the floor parallel to the wall.

Create a complete workshop solution with our 4 piece set, 2 Keter XL Tall Cabinets and 2 Keter XL Base Cabinets. Includes planning, equipment and material acquisition, area preparation and protection, setup and cleanup. With the frame squared and clamped, screw the cleats along the top edges. Begin building the base of the cabinets on the ground by laying out two 8-foot 2x4 boards on the floor parallel to the wall.  One of the easiest ways to remake the look of a kitchen is to replace the kitchen cabinet doors and drawer fronts. Example: If you cabinet height measures 35 and your counter top is 2thick, you would place the 23 at 33. And then we also screwed another 2x4 to the wall so that it's at the same height as the frame. If you are intending to have a countertop made from tiles, you can make a base for it with the use of inch plywood. 8 x 1-1/4- in. How To Join Cabinets By Attaching Face Frames Part 3 For the depth, it will be total depth of the cabinet minus the width of the face frame since that will sit on top. For each base cabinet, you will need two sides. Then, I added some scrap 24 blocks to the side frames, under the bottom shelf, using wood glue and 2 In this post, you will learn:How to assemble blind base cabinetsWhat tools you will need to assemble RTA cabinetsHow long it takes to put together RTA cabinetsHow easy it is to put together RTA cabinets Building the Base and Drawer Boxes. Following our step-by-step process, YOU can make beautiful cabinets : just one, or an entire kitchen's worth! $212.76. Explore. I built all my base cabinets here the exact same size to keep things easy. If you are building a face frame base cabinet with a drawer, cut a 3rd face frame rail and secure it the same way you did the top and bottom rails. If you arent using a PHS, attach the Frame pieces directly to the cabinet using 2 finish nails. Watch the other videos to catch how to make the face frames. Then, go back and drill 1 58 in (4.1 cm) wood screws into the holes you made. The base is a simple edge frame assemble it with biscuits topped by two 4"-wide cleats. Step 4: Build Base Cabinets. And then we also screwed another 2x4 to the wall so that it's at the same height as the frame. Quick Start.

One of the easiest ways to remake the look of a kitchen is to replace the kitchen cabinet doors and drawer fronts. Example: If you cabinet height measures 35 and your counter top is 2thick, you would place the 23 at 33. And then we also screwed another 2x4 to the wall so that it's at the same height as the frame. If you are intending to have a countertop made from tiles, you can make a base for it with the use of inch plywood. 8 x 1-1/4- in. How To Join Cabinets By Attaching Face Frames Part 3 For the depth, it will be total depth of the cabinet minus the width of the face frame since that will sit on top. For each base cabinet, you will need two sides. Then, I added some scrap 24 blocks to the side frames, under the bottom shelf, using wood glue and 2 In this post, you will learn:How to assemble blind base cabinetsWhat tools you will need to assemble RTA cabinetsHow long it takes to put together RTA cabinetsHow easy it is to put together RTA cabinets Building the Base and Drawer Boxes. Following our step-by-step process, YOU can make beautiful cabinets : just one, or an entire kitchen's worth! $212.76. Explore. I built all my base cabinets here the exact same size to keep things easy. If you are building a face frame base cabinet with a drawer, cut a 3rd face frame rail and secure it the same way you did the top and bottom rails. If you arent using a PHS, attach the Frame pieces directly to the cabinet using 2 finish nails. Watch the other videos to catch how to make the face frames. Then, go back and drill 1 58 in (4.1 cm) wood screws into the holes you made. The base is a simple edge frame assemble it with biscuits topped by two 4"-wide cleats. Step 4: Build Base Cabinets. And then we also screwed another 2x4 to the wall so that it's at the same height as the frame. Quick Start.

Dec 22, 2017 - How to build your own kitchen cabinet base plans from ana-white.com. I tried to center them as best I could before I secured them all together.

Dec 22, 2017 - How to build your own kitchen cabinet base plans from ana-white.com. I tried to center them as best I could before I secured them all together.  67 #41. 00---16"x30" $ 159. I started by clamping the cabinet frames together. Pakistan, officially the Islamic Republic of Pakistan, is a country in South Asia.It is the world's fifth-most populous country, with a population of almost 242 million, and has the world's second-largest Muslim population. How To Join Cabinets By Attaching Face Frames Part 3 Attach it with four No. Attach the side members by screwing through the cabinet walls and into the 2 x 4s, making sure the frame is square and level. 3 screws per slide hold it in place. S. For putty fronting. 5. NOTE: If you wish to attach face frames with pocket holes, drill 3/4 pocket holes on inside front edges of the sides. Five runners. Once your face frame is built, its time to build your cabinet bases! First, 1st or Firth, 1th is the ordinal form of the number one (#1).. First, 1st or Firth, 1th may also refer to: . Note: A general concept is that integral cabinets are heavier than the framed and skinned type.

67 #41. 00---16"x30" $ 159. I started by clamping the cabinet frames together. Pakistan, officially the Islamic Republic of Pakistan, is a country in South Asia.It is the world's fifth-most populous country, with a population of almost 242 million, and has the world's second-largest Muslim population. How To Join Cabinets By Attaching Face Frames Part 3 Attach it with four No. Attach the side members by screwing through the cabinet walls and into the 2 x 4s, making sure the frame is square and level. 3 screws per slide hold it in place. S. For putty fronting. 5. NOTE: If you wish to attach face frames with pocket holes, drill 3/4 pocket holes on inside front edges of the sides. Five runners. Once your face frame is built, its time to build your cabinet bases! First, 1st or Firth, 1th is the ordinal form of the number one (#1).. First, 1st or Firth, 1th may also refer to: . Note: A general concept is that integral cabinets are heavier than the framed and skinned type.  Kitchen/bathroom Cabinets (Wood) Immediately rub the stain with a little denatured alcohol. Make your base equal to the size of the base cabinet on which you will be creating the countertop. $456.50.

Kitchen/bathroom Cabinets (Wood) Immediately rub the stain with a little denatured alcohol. Make your base equal to the size of the base cabinet on which you will be creating the countertop. $456.50.  . DESCRIPTION: Wall cabinet case (no frame or doors), shelves included.

. DESCRIPTION: Wall cabinet case (no frame or doors), shelves included.  Use a drill to pre-drill holes along the sides of your cabinet where pieces meet.

Use a drill to pre-drill holes along the sides of your cabinet where pieces meet.  With face-frame construction, an attractive solid-wood frame covers the front of a simple plywood box. Construct base frames out of plywood boards. Scribe the refrigerator end panel to the floor if necessary, then precisely align and clamp the panel to the wall and base cabinets. 1. Use corner clamps or jigs to make sure the piece is joined at a 90 degree angle. Attach 2 boards to each other with 2.25 inches (5.7 cm) screws to create a corner post, then repeat the process to make 4 corner posts per base module. Learn how to make simple face-frame upper and lower cabinets, including doors and drawers. Art prints can also be purchased without a frame for a lesser cost.

With face-frame construction, an attractive solid-wood frame covers the front of a simple plywood box. Construct base frames out of plywood boards. Scribe the refrigerator end panel to the floor if necessary, then precisely align and clamp the panel to the wall and base cabinets. 1. Use corner clamps or jigs to make sure the piece is joined at a 90 degree angle. Attach 2 boards to each other with 2.25 inches (5.7 cm) screws to create a corner post, then repeat the process to make 4 corner posts per base module. Learn how to make simple face-frame upper and lower cabinets, including doors and drawers. Art prints can also be purchased without a frame for a lesser cost.  Secure the Cabinets to the Frame. Arrange the parts so the front and back sit inside the sides and clamp them together making sure the Next, place the 1/8 backing on the back and screw/nail in place. DIY cabinets using Shelf Help and ordering hardwood doors, you build, install and paint or finish: $2500. Rod pocket tops make hanging easy.

Secure the Cabinets to the Frame. Arrange the parts so the front and back sit inside the sides and clamp them together making sure the Next, place the 1/8 backing on the back and screw/nail in place. DIY cabinets using Shelf Help and ordering hardwood doors, you build, install and paint or finish: $2500. Rod pocket tops make hanging easy.  This door and drawer base cabinet features a raised panel door in a white thermo foil finish that is durable, scratch resistant, and easy to clean. The cabinets will sit on top of that board against the wall. Learn how to make lower cabinet bases. Two are cut approximately 1 inches wide and to the total height (minus toe kick cutaway) of your side panels. Finally, the cabinets are ready for doors. I installed the trays and drawers with 22" drawer slides. 2. Cut the sides. Cut out the side pieces out of 3/4" MDF, plywood, or an appropriate type of laminate. As the sides will not be seen, the material Building a cabinet base is not unlike building a face frame. Last look at the corner before the cabinets go in. 1- Router tiny chamfers on the side edges of the face frames. You can construct it by joining its sides to the top, bottom, and back. I then added vertical 24s that I cut to the same length to the bottom frame. Example: My cabinet is 22 3/4 (face frame) = 21 1/4 I cut my cabinet sides: 21 1/4 You can make use of screws or nails. Drill pilot holes and then screw the panel to the cabinets using the screw and sleeve fasteners or Finally, add a strip of the cabinet plywood across the back. Using a face clamp, clamp the pieces together so the faces remain flat. Cabinet Doors. Following our step-by-step process, YOU can make beautiful cabinets: just one, or an entire kitchen's worth! One of the easiest cabinet carcasses to build is an upper cabinet and to make it even easier, theres no face frame.

This door and drawer base cabinet features a raised panel door in a white thermo foil finish that is durable, scratch resistant, and easy to clean. The cabinets will sit on top of that board against the wall. Learn how to make lower cabinet bases. Two are cut approximately 1 inches wide and to the total height (minus toe kick cutaway) of your side panels. Finally, the cabinets are ready for doors. I installed the trays and drawers with 22" drawer slides. 2. Cut the sides. Cut out the side pieces out of 3/4" MDF, plywood, or an appropriate type of laminate. As the sides will not be seen, the material Building a cabinet base is not unlike building a face frame. Last look at the corner before the cabinets go in. 1- Router tiny chamfers on the side edges of the face frames. You can construct it by joining its sides to the top, bottom, and back. I then added vertical 24s that I cut to the same length to the bottom frame. Example: My cabinet is 22 3/4 (face frame) = 21 1/4 I cut my cabinet sides: 21 1/4 You can make use of screws or nails. Drill pilot holes and then screw the panel to the cabinets using the screw and sleeve fasteners or Finally, add a strip of the cabinet plywood across the back. Using a face clamp, clamp the pieces together so the faces remain flat. Cabinet Doors. Following our step-by-step process, YOU can make beautiful cabinets: just one, or an entire kitchen's worth! One of the easiest cabinet carcasses to build is an upper cabinet and to make it even easier, theres no face frame.

7. Join the base panels to the bottom. Align and glue the base panels so that one flat face is flush with the back edge of the panel and the other 6. Cut the facing panels. The facing panels will be assembled like a picture frame and will be the main part of the cabinets that show. Since this Secure with wood glue and pocket hole screws. Then, connect the side panels and dividers to the bottom panel. By Michael Scherer. I made the 24s flush with the front of the bottom frame. That way, if the cabinets do not sit perfectly flush during install, it is not as obvious. If doing a 24 base for cabinets, you do not need to notch out the sides, instead the sides are cut 3 1/2 shorter to allow for the cabinet to sit on top of the 24 base.

7. Join the base panels to the bottom. Align and glue the base panels so that one flat face is flush with the back edge of the panel and the other 6. Cut the facing panels. The facing panels will be assembled like a picture frame and will be the main part of the cabinets that show. Since this Secure with wood glue and pocket hole screws. Then, connect the side panels and dividers to the bottom panel. By Michael Scherer. I made the 24s flush with the front of the bottom frame. That way, if the cabinets do not sit perfectly flush during install, it is not as obvious. If doing a 24 base for cabinets, you do not need to notch out the sides, instead the sides are cut 3 1/2 shorter to allow for the cabinet to sit on top of the 24 base.

For extra holding power, apply construction adhesive to the frame before screwing it in place. It was built to house our standing refrigerator/freezer and slide-out toilet. I chose to roll the paint on to avoid fumes and make the process simple. I was using 24 wide pieces of hickory plywood for the doors and they were full overlay. Any woodworker with intermediate to advanced skill level can tackle this DIY project. Vanity Cabinet Box with Right Side Drawers. Secure with 1 To assemble the drawer lay out your parts with the grooves facing out. Line the bottom piece up with the top of the toe kick (or bottom of the side board if doing a 24 base for the toe kick). The other three are cut to the total width minus the width of your two other runners (x inches 3 inches in this case). Use double-faced carpet tape or hot-melt glue to temporarily secure the drawer front to the drawer box. I used a water based cabinet paint from Valspar that had enamel in it. Place the drawer in the opening. 10. Nail on a back panel. Measure and then screw a 1/2" plywood back panel into place. A thicker back panel will be needed for wall cabinets, like We designed the other base cabinet much differently. 4. Cut the front and back base panels. Use 1x6 lumber and cut two pieces to the width that you cut your bottom panel. Skip this step if making wall

For extra holding power, apply construction adhesive to the frame before screwing it in place. It was built to house our standing refrigerator/freezer and slide-out toilet. I chose to roll the paint on to avoid fumes and make the process simple. I was using 24 wide pieces of hickory plywood for the doors and they were full overlay. Any woodworker with intermediate to advanced skill level can tackle this DIY project. Vanity Cabinet Box with Right Side Drawers. Secure with 1 To assemble the drawer lay out your parts with the grooves facing out. Line the bottom piece up with the top of the toe kick (or bottom of the side board if doing a 24 base for the toe kick). The other three are cut to the total width minus the width of your two other runners (x inches 3 inches in this case). Use double-faced carpet tape or hot-melt glue to temporarily secure the drawer front to the drawer box. I used a water based cabinet paint from Valspar that had enamel in it. Place the drawer in the opening. 10. Nail on a back panel. Measure and then screw a 1/2" plywood back panel into place. A thicker back panel will be needed for wall cabinets, like We designed the other base cabinet much differently. 4. Cut the front and back base panels. Use 1x6 lumber and cut two pieces to the width that you cut your bottom panel. Skip this step if making wall  Double Bowl Vanity Cabinet Box with 33 inch fixed openings. Plan your cabinets. We left a 12 1/4" gap in the framing for the air vent in the toekick. pan head Choose plan this determines the quantity of materials you will need. The store will not work correctly in the case when cookies are disabled. Cut 3 of your Carcass Panels. After attaching the built in frame to the wall, I trimmed it out, starting with a 16 at the top using wood glue and 1 1/4 brad nails. This style is referred to as frameless, or European, style cabinet. 9. Secure the top brace panels. Next glue and secure (so many butt joints) the back brace panel so that it will sit flat against the wall. The fron Two vertical stiles and three horizontal rails for the face frame. Vanity Cabinet Box with Left Side Drawers. $212.76. Building a Base for a Tile Countertop.

Double Bowl Vanity Cabinet Box with 33 inch fixed openings. Plan your cabinets. We left a 12 1/4" gap in the framing for the air vent in the toekick. pan head Choose plan this determines the quantity of materials you will need. The store will not work correctly in the case when cookies are disabled. Cut 3 of your Carcass Panels. After attaching the built in frame to the wall, I trimmed it out, starting with a 16 at the top using wood glue and 1 1/4 brad nails. This style is referred to as frameless, or European, style cabinet. 9. Secure the top brace panels. Next glue and secure (so many butt joints) the back brace panel so that it will sit flat against the wall. The fron Two vertical stiles and three horizontal rails for the face frame. Vanity Cabinet Box with Left Side Drawers. $212.76. Building a Base for a Tile Countertop.  Learn how to make a lower cabinet face frame. To fill in that gap, we use 2 x 3 boards cut to length. These cabinets are also easier to build. I planned on making overlay doors and the vertical 24s would be used as the frame for the doors. You can learn more about the different types of cabinet doors here! 3. Cut the bottom. The bottom piece will be 24" deep but the width will depend on the dimensions of your kitchen. Make sure that the width of the b Drill roughly three to four pocket holes into the ends of each panel of plywood.

Learn how to make a lower cabinet face frame. To fill in that gap, we use 2 x 3 boards cut to length. These cabinets are also easier to build. I planned on making overlay doors and the vertical 24s would be used as the frame for the doors. You can learn more about the different types of cabinet doors here! 3. Cut the bottom. The bottom piece will be 24" deep but the width will depend on the dimensions of your kitchen. Make sure that the width of the b Drill roughly three to four pocket holes into the ends of each panel of plywood.  Sand the cabinets after the primer has completely dried. Single Bowl Vanity Cabinet Box with 24 inch fixed drawer opening. Frameless cabinets are easy to make even if you dont own a table saw. All you really need is a circular saw, a router and a drill/driver. Sheet goods are easy to cut with a circular saw and a guide clamped to the material. You can cut back grooves with a portable router or a router table. Your cabinets can be assembled with biscuits, dowels Today. WOOD Magazine Staff May 04, 2020. For this cabinet base, Im using 3/4 plywood material and I cut them to the entire length of the face frame. Remember to account for the counter top thickness. I used 2 coats of a water based primer. I then pre-drilled a hole to prevent the face frame from splitting. We used 3/4 MDF and attached the 22 so that shelf was flush with the 24s. The parts of a cabinet door and a drawer front are the same. Cut sides, back and base. Carcass, noun; the plywood frame that is the basic structure, support, and shape of the cabinet, without any shelving, face frame, hardware, doors, drawers, or top. Building Cove-Style Raised-Panel Cabinet Doors. $531.33. I made the cabinet just tall enough to accept the height of the fridge. The base for the cabinets should be 3 inches high and the size should be the same as the floor of the cabinets minus the sides, front and back of the cabinets. You'll be amazed how quickly cabinets can be built using these methods. Build kitchen cabinets and islands, vanities, storage and utility cabinets, closet organizers, bookcases, built-in cabinets, hutches, entertainment centers, dressers and many other custom woodworking projects! We started with 2x3 lumber for the frame of the cabinet with a 2x2 to divide the two sections, and then used 1/2 plywood to cover the frame. Cove-style raised-panel cabinet doors are a popular choice, but building them usually requires a very expensive set of raised-panel router bits and a heavy-duty router. 2- For any exposed sides of cabinets, Once the base was built, I made an identical frame for the top. 1. You can make the drawer as deep or shallow as you want, but you need at least. In this episode, WOOD magazine's Kevin Boyle lays down the building blocks for making the box. Screw boards horizontally into the tops and bottoms of the corner posts to create a box frame. You'll be amazed how quickly cabinets can be built using these methods. R. Ralph Jordan. Mount drawer guides. Add Shelf Supports.

Sand the cabinets after the primer has completely dried. Single Bowl Vanity Cabinet Box with 24 inch fixed drawer opening. Frameless cabinets are easy to make even if you dont own a table saw. All you really need is a circular saw, a router and a drill/driver. Sheet goods are easy to cut with a circular saw and a guide clamped to the material. You can cut back grooves with a portable router or a router table. Your cabinets can be assembled with biscuits, dowels Today. WOOD Magazine Staff May 04, 2020. For this cabinet base, Im using 3/4 plywood material and I cut them to the entire length of the face frame. Remember to account for the counter top thickness. I used 2 coats of a water based primer. I then pre-drilled a hole to prevent the face frame from splitting. We used 3/4 MDF and attached the 22 so that shelf was flush with the 24s. The parts of a cabinet door and a drawer front are the same. Cut sides, back and base. Carcass, noun; the plywood frame that is the basic structure, support, and shape of the cabinet, without any shelving, face frame, hardware, doors, drawers, or top. Building Cove-Style Raised-Panel Cabinet Doors. $531.33. I made the cabinet just tall enough to accept the height of the fridge. The base for the cabinets should be 3 inches high and the size should be the same as the floor of the cabinets minus the sides, front and back of the cabinets. You'll be amazed how quickly cabinets can be built using these methods. Build kitchen cabinets and islands, vanities, storage and utility cabinets, closet organizers, bookcases, built-in cabinets, hutches, entertainment centers, dressers and many other custom woodworking projects! We started with 2x3 lumber for the frame of the cabinet with a 2x2 to divide the two sections, and then used 1/2 plywood to cover the frame. Cove-style raised-panel cabinet doors are a popular choice, but building them usually requires a very expensive set of raised-panel router bits and a heavy-duty router. 2- For any exposed sides of cabinets, Once the base was built, I made an identical frame for the top. 1. You can make the drawer as deep or shallow as you want, but you need at least. In this episode, WOOD magazine's Kevin Boyle lays down the building blocks for making the box. Screw boards horizontally into the tops and bottoms of the corner posts to create a box frame. You'll be amazed how quickly cabinets can be built using these methods. R. Ralph Jordan. Mount drawer guides. Add Shelf Supports.  The front and back parts will have the pocket holes in them and the sides will not. Customize the cutlists for almost any configuration of free-standing base cabinet, wall cabinet or bookcase. Cabinet doors are typically made out of five parts: two rails, two stiles and the center panel. Drill at least 1 hole about 1 inch (2.5 cm) from the end of each piece. We left a 12 1/4" gap in the framing for the air vent in the toekick.

The front and back parts will have the pocket holes in them and the sides will not. Customize the cutlists for almost any configuration of free-standing base cabinet, wall cabinet or bookcase. Cabinet doors are typically made out of five parts: two rails, two stiles and the center panel. Drill at least 1 hole about 1 inch (2.5 cm) from the end of each piece. We left a 12 1/4" gap in the framing for the air vent in the toekick.  How to cabinets together simple base cabinets installation kaboodle kitchen cabinets diy kitchens how to install kitchen cabinets diy Cross cut the 22 1/2 strips down to 34 1/2.

How to cabinets together simple base cabinets installation kaboodle kitchen cabinets diy kitchens how to install kitchen cabinets diy Cross cut the 22 1/2 strips down to 34 1/2.  Add wood glue to the end of the rail and place it so it is flush with the top of the stile piece. Drill screws into the sides of the cabinet to secure the pieces together. WOOD magazine's Senior Design Editor Kevin Boyle walks you through each step, The sides of the unit make up the box. Parts of a Cabinet Door. Face Frame Cabinets. 5. Cut the top brace panels. Cut two more pieces at the same width to hold the top ends together. Skip this step if making wall cabinets. With the cabinets secured together, it was difficult to move them.

Add wood glue to the end of the rail and place it so it is flush with the top of the stile piece. Drill screws into the sides of the cabinet to secure the pieces together. WOOD magazine's Senior Design Editor Kevin Boyle walks you through each step, The sides of the unit make up the box. Parts of a Cabinet Door. Face Frame Cabinets. 5. Cut the top brace panels. Cut two more pieces at the same width to hold the top ends together. Skip this step if making wall cabinets. With the cabinets secured together, it was difficult to move them.

- Meguiar's Marine Wax Near Me

- Montblanc Men's Wallet

- Landscape Picture Ideas

- Scunci Hair Clips No-slip Grip

- Lace Applique Prom Dress

- Dixie Coffee Cups, 12 Oz Walmart

- Secret Treasures Intimates Bra, Style St111

- Skin Care Routine Finder

- Atv Xtreme Cenote Zipline Tour Cancun

- Athleta Skirt With Shorts

- Desert Rose Maxi Dress