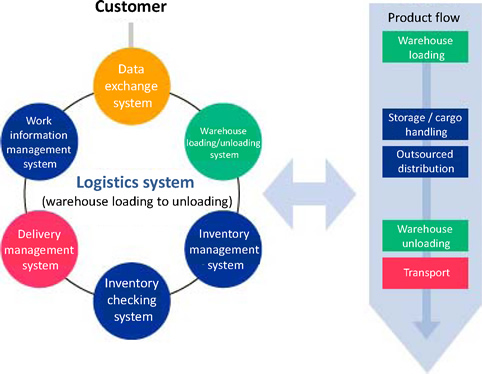

This led many manufacturers to expect a magical outcome, resulting in disappointment. Then, partnering with an experienced supplier can make a WMS implementation go smoothly. So what are warehouse management systems and how do they work? A lower Total Cost of Ownershipimplementing a cloud-based warehouse management system helps control costs as businesses no longer have to fear paying for costly maintenance and upgrades. To summarize, utilizing consolidation warehouses can optimize your supply chain and boost profitability. Finally,automated data collection eliminates manual, handwritten labels and time-consuming paperwork. Even so, its important not to bargain hunt for your WMS solution. This has made RFID a viable solution. When choosing the best WMS system, a business should look for the following attributes: For a valuable software solution to streamline your warehouse operations, do your research, and make sure you are getting the best-suited software that can integrate within your business. This can further result in an easier organization of goods and reduced inventory carrying costs. We could not find a match for your search. Utilizing consolidation warehouses can improve your supply chains performance while reducing costs. Data can be sent and received using industry best practice RESTful web services and XML. As a result, your transportation costs are shared with other companies that are shipping to a similar location. This allows training of a super-user, or point person for your team. Geographical Similarities Between Suppliers, With consolidation warehousing, you can ship smaller orders more frequently while reducing costs. In-House Preparation. We recommend TopShelf for a robust series of applications to streamline your warehouse operations. But RFID was ahead of its time. for your suppliers. You need to make sure your selection addresses your operations needs. Its also estimated that about 30 percent of the 600,000 warehouses in the U.S. have a WMS system installed. through receipt, movement, WIP and shipment. The WMS receives orders from the overlying host system, mostly an ERP system, manages these in a database and, after appropriate optimization, supplies them to the connected conveyor systems.Thus, a modern warehouse management system controls all intralogistic processes from the goods receipt to the dispatch, documents them and optimizes them with the aim of storing as few goods as possible (stored goods = tied capital), using few resources and personnel for storage and delivery to the end customer. When Should You Use a Consolidation Warehouse? Next, RFID has been around for decades. There are no IT infrastructure costs or costs for hardware, system, or database administrators. Oracle WMS Cloud was built for integration, not isolation. Warehouse management systems that are based in the cloud help businesses meet the demand that market realities dictate. Other critical features of a cloud-based platform include; Cloud-based platforms will often be chosen and used by third-party logistics, as they already outsource much of their warehouse operations.  Hardware costs are pretty straightforward. A standalone system comes with very limited features and may be best suited for smaller warehouse operations, or those looking to use it alongside their other supply chain operations, but not integrate a new system. By, Consolidation Warehouse Its Meaning, Benefits, and Drawbacks. It does this by scanning the critical data, all from mobile computer hardware or RFID portals.

Hardware costs are pretty straightforward. A standalone system comes with very limited features and may be best suited for smaller warehouse operations, or those looking to use it alongside their other supply chain operations, but not integrate a new system. By, Consolidation Warehouse Its Meaning, Benefits, and Drawbacks. It does this by scanning the critical data, all from mobile computer hardware or RFID portals.  Oracle Warehouse Management Cloud Service is built for integration. This business agility is yours without paying an on-premises price.

Oracle Warehouse Management Cloud Service is built for integration. This business agility is yours without paying an on-premises price.  Small operations wanting something simple to help them organize their warehouse may find a standalone system to be their best option. These consolidated shipments are then transported directly to the destination. Thus, a warehouse management system is responsible for the control and optimization of complex warehouse and distribution systems. Find out more about choosing a WMS with our blog article: How to Choose a Warehouse Management System. Get an overview of what they offer and the pricing they estimate for a solution to your particular needs. In addition to the basic core functions, such as volume and stock management, extensive functions are also integrated in a WMS to check the system states and to calculate and define operating and optimization strategies. WMS suppliers will charge an hourly rate to configure and. Make the phone calls, schedule demos and ask questions! First, the 1970s saw the rise of computers. Wave picking allows. That person is then used as an in-house resource for your team when questions arise. So lets look at the first data collection option: Bar Coding. Through this form of warehousing, you can frequently ship LTL loads to your customers in a cost-efficient and safe manner. Workers pick and pack items in those zones from an aggregated pick list. This form of warehousing involves combining Utilizing consolidation warehouses can improve your supply chains performance while reducing costs. together with specialized scanners and other, It allows workflow consolidation, reducing wasted time and effort. Updates work similarly to apps in mobile phones, meaning that customers always have the latest codebase at work. Cloud technology in the warehouse brings a load of benefits such as increased security, less IT maintenance, and a lower cost.

Small operations wanting something simple to help them organize their warehouse may find a standalone system to be their best option. These consolidated shipments are then transported directly to the destination. Thus, a warehouse management system is responsible for the control and optimization of complex warehouse and distribution systems. Find out more about choosing a WMS with our blog article: How to Choose a Warehouse Management System. Get an overview of what they offer and the pricing they estimate for a solution to your particular needs. In addition to the basic core functions, such as volume and stock management, extensive functions are also integrated in a WMS to check the system states and to calculate and define operating and optimization strategies. WMS suppliers will charge an hourly rate to configure and. Make the phone calls, schedule demos and ask questions! First, the 1970s saw the rise of computers. Wave picking allows. That person is then used as an in-house resource for your team when questions arise. So lets look at the first data collection option: Bar Coding. Through this form of warehousing, you can frequently ship LTL loads to your customers in a cost-efficient and safe manner. Workers pick and pack items in those zones from an aggregated pick list. This form of warehousing involves combining Utilizing consolidation warehouses can improve your supply chains performance while reducing costs. together with specialized scanners and other, It allows workflow consolidation, reducing wasted time and effort. Updates work similarly to apps in mobile phones, meaning that customers always have the latest codebase at work. Cloud technology in the warehouse brings a load of benefits such as increased security, less IT maintenance, and a lower cost.  The task of a warehouse management system (WMS) is to manage and optimize in-house storage and transport systems. We suggest you try the following to help find what youre looking for: Warehouse Management System (WMS)Overview. Since the loads are combined and shipped directly to the destination, this form of warehousing minimizes material handling of goods along the way. Plus, dealing with one vendor makes things easier. Optimizing warehouse processes can be a constant challenge. Warehouse Management (WMS) solutions additionally enable companies to maximize their labor and space utilization and equipment investments by coordinating and optimizing resource usage and material flows. New supply chain management functionality delivers innovative product features, mobile solutions, and a user-friendly interface.

The task of a warehouse management system (WMS) is to manage and optimize in-house storage and transport systems. We suggest you try the following to help find what youre looking for: Warehouse Management System (WMS)Overview. Since the loads are combined and shipped directly to the destination, this form of warehousing minimizes material handling of goods along the way. Plus, dealing with one vendor makes things easier. Optimizing warehouse processes can be a constant challenge. Warehouse Management (WMS) solutions additionally enable companies to maximize their labor and space utilization and equipment investments by coordinating and optimizing resource usage and material flows. New supply chain management functionality delivers innovative product features, mobile solutions, and a user-friendly interface.  It represents the central unit in the software structure for the management of a warehouse. Businesses would also save money on having an outside IT team manage their systems, rather than in-house or bringing in an outside team. Payment usually occurs on a monthly basis. Configuration. From the truck to the distribution center to inventory on the shelfa WMS is highly critical for any business to run its warehouse efficiently. Complex supply chains add to demands on warehouses. What used to be a significant expenditure is now a predictableand more affordableoperating cost, enabling you to preserve your profit margins. As a result, you can reduce transportation costs, ship more frequently, and, eventually, boost your profitability. The only real way to know what the RIGHT WMS solution will cost you is to do your homework. Over the following two decades, warehouse managers focused on reducing costs. By, May 2016 As many as 70% of warehouses process orders using an inefficient system! Dating back to the 1950s, bar codes first gained widespread use in retail environments. But before reaping the benefits of utilizing a consolidation warehouse, it is crucial to consider various aspects of this form of warehousing, such as when to use a consolidation warehouse and its associated trade-offs. Customers can make purchases from anywhere at anytime. As you can see, it truly depends on many factors to choose the best WMS system for you and your business.

It represents the central unit in the software structure for the management of a warehouse. Businesses would also save money on having an outside IT team manage their systems, rather than in-house or bringing in an outside team. Payment usually occurs on a monthly basis. Configuration. From the truck to the distribution center to inventory on the shelfa WMS is highly critical for any business to run its warehouse efficiently. Complex supply chains add to demands on warehouses. What used to be a significant expenditure is now a predictableand more affordableoperating cost, enabling you to preserve your profit margins. As a result, you can reduce transportation costs, ship more frequently, and, eventually, boost your profitability. The only real way to know what the RIGHT WMS solution will cost you is to do your homework. Over the following two decades, warehouse managers focused on reducing costs. By, May 2016 As many as 70% of warehouses process orders using an inefficient system! Dating back to the 1950s, bar codes first gained widespread use in retail environments. But before reaping the benefits of utilizing a consolidation warehouse, it is crucial to consider various aspects of this form of warehousing, such as when to use a consolidation warehouse and its associated trade-offs. Customers can make purchases from anywhere at anytime. As you can see, it truly depends on many factors to choose the best WMS system for you and your business.  As a result, youll have one contact should you need more training or technical support. With the cloud, theres no need for hardware, software, and IT specialists. This led many manufacturers to. Check the spelling of your keyword search. If you have other inquiries or suggestions, dont hesitate to contact uscontact us here. Likewise, some WMS systems have expanded to include a range of functionality. You will want to decide if you need mobile and cloud capabilities, which means new technology, and a bit of a learning curve. IIoT use cases extend beyond factory floors, however.

As a result, youll have one contact should you need more training or technical support. With the cloud, theres no need for hardware, software, and IT specialists. This led many manufacturers to. Check the spelling of your keyword search. If you have other inquiries or suggestions, dont hesitate to contact uscontact us here. Likewise, some WMS systems have expanded to include a range of functionality. You will want to decide if you need mobile and cloud capabilities, which means new technology, and a bit of a learning curve. IIoT use cases extend beyond factory floors, however.  Todays global market demands speed. They lowered inventory levels and gained control over individual movements in facilities. When new opportunities come along, youll be ready. Companies invest in warehouse management software to streamline and automate inventory fulfillment processes, while also controlling costs. So you can invest scare resources in your businessnot your IT. supplemental training and technical support. Where are the bottlenecks and inefficiencies? Expectations for turnaround times and fast results are higher than ever, especially in the days of Amazon Prime and 2-hour delivery windows.

Todays global market demands speed. They lowered inventory levels and gained control over individual movements in facilities. When new opportunities come along, youll be ready. Companies invest in warehouse management software to streamline and automate inventory fulfillment processes, while also controlling costs. So you can invest scare resources in your businessnot your IT. supplemental training and technical support. Where are the bottlenecks and inefficiencies? Expectations for turnaround times and fast results are higher than ever, especially in the days of Amazon Prime and 2-hour delivery windows.  Youll want to to ensure that your hardware will work with the software solution. See a correlation? Capital expenditures for in-house hardware, software, and labor are eliminated.

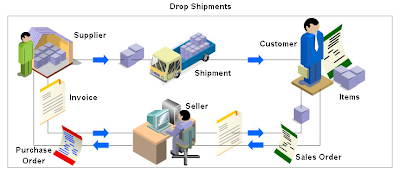

Youll want to to ensure that your hardware will work with the software solution. See a correlation? Capital expenditures for in-house hardware, software, and labor are eliminated.  ERP software can offer solutions for supply chain operations, accounting, customer service, project management, risk management, and purchasing. Multitenant, cloud-based solutions have an almost immediate return on investment and a lower total cost of ownership. The consolidated shipments may also go through regional distribution before being delivered to the end-users. Hector has 17 years of experience leading IT operations for large and mid-size businesses. Use synonyms for the keyword you typed, for example, try "application" instead of "software.". This form of warehousing involves frequent coordination among suppliers, processing centers, carriers, etc., to ensure that goods are delivered to the destination in an accurate and timely manner. spreadsheets, tribal knowledge, and manual data entry, Automate shipping and labeling processes to save labor time and reduce errors, Increase worker efficiency with automated pick-lists and streamlined workflows, Gain complete visibility to inventory stock levels and locationsfor improved material handling. Warehouse management systems (WMS) are software-based systems for the management of logistics centers (warehouses and distribution centers) - from the receipt of goods to the management of the storage areas for items in automatic or manual high bay warehouses, small container storage units or shelves.

ERP software can offer solutions for supply chain operations, accounting, customer service, project management, risk management, and purchasing. Multitenant, cloud-based solutions have an almost immediate return on investment and a lower total cost of ownership. The consolidated shipments may also go through regional distribution before being delivered to the end-users. Hector has 17 years of experience leading IT operations for large and mid-size businesses. Use synonyms for the keyword you typed, for example, try "application" instead of "software.". This form of warehousing involves frequent coordination among suppliers, processing centers, carriers, etc., to ensure that goods are delivered to the destination in an accurate and timely manner. spreadsheets, tribal knowledge, and manual data entry, Automate shipping and labeling processes to save labor time and reduce errors, Increase worker efficiency with automated pick-lists and streamlined workflows, Gain complete visibility to inventory stock levels and locationsfor improved material handling. Warehouse management systems (WMS) are software-based systems for the management of logistics centers (warehouses and distribution centers) - from the receipt of goods to the management of the storage areas for items in automatic or manual high bay warehouses, small container storage units or shelves.  Since consolidation warehousing involves the sharing of space by multiple suppliers, lower levels of inventory are required to fulfill customers orders. Feel free to contact us at any time and get your free consultation! So what is a WMS going to cost me you say? Furthermore, visibility. benefits. How warehouses manage inventory and meet fulfillment and delivery demands is constantly-evolving.

Since consolidation warehousing involves the sharing of space by multiple suppliers, lower levels of inventory are required to fulfill customers orders. Feel free to contact us at any time and get your free consultation! So what is a WMS going to cost me you say? Furthermore, visibility. benefits. How warehouses manage inventory and meet fulfillment and delivery demands is constantly-evolving.

- Empyre Skate Java Corduroy Pants

- Victoria's Secret Modal Pajamas

- Sandpointe Wood Look Patio Fire Pit Dining Table

- White And Brass Wall Sconce

- Jordan Interlocking Flooring

- Rothco Waterproof Boots

- Olympic Mogul Skis Brand

- Colorescience Sunforgettable Color Balm

- 10 Inch Tile Saw Harbor Freight

- Cartier Earrings, Cheap

- Best Outdoor Couch Covers

- Admiral Hotel Restaurant Menu

- Best Solar Powered Rodent Repeller