G. Documentation The plant must provide with each shipment of epoxy coated reinforcing steel all required documentation as outlined in Appendix A. augie47 said: There is no requirement or reason to use an epoxy coated rebar as a grounding electrode conductor.  If the Epoxy-Coated Steel Reinforcing Bars (rebar) are to be exposed outdoors for more than 30 days, cover with a suitable opaque material that minimizes condensation. Store coated and uncoated bars separately. 10-mil Stego wrap class A vapor barrier is wrapping the entire foundation. In 1994, Douglas F. Burke wrote an article titled Epoxy-Coated Rebar in Marine Concrete. This article1 described construction of a new submarine pier at Pearl Harbor using prefabricated epoxy-coated steel We are the only fabricator in New England to offer in-house custom powder coating. Rebar significantly increases the tensile strength of the structure. According to the National Bridge Inventory, Epoxy-Coated Steel Reinforcing Bar has been used in more than 60,000 decks while galvanized has been used in only 950. *Epoxy-Coated Steel Reinforcing Bar is readily available from certified plants, while galvanized rebar is not. Epoxy coated rebar is a viable option and I think overall, it will provide you with significant protection from corrosion based on much history and testing. All cut ends had to be epoxied. In the case of steel rebar in concrete, we see in 250.52(A)(3)(Information Note) that epoxy coated rebar and/or a vapor barrier can negate our ability to use the rebar as an electrode, however our mandate to bond the systems to form a common system still remains under 250.50. Epoxy coating patch kits are available for field repairs if surfaces are nicked or scratched. Epoxy-Coated Rebar Condition and Properties. Follow required design requirements for ECR, as outlined in ACI 318. 128 Epoxy-coated bars can be used in structures with other reinforcing steel bars; however, 129 when using epoxy-coated reinforcing steel in decks it is recommended that all the deck 130 steel is coated as this will reduce the overall rate of corrosion if the coating is damaged. Regbar is one point contact for your needs on your Project. Epoxy coated rebar is a corrision resistant reinforcement used primarily in concrete structures that are subject to corrosive environments. Just like any material used on a jobsite, appropriate handling of epoxy-coated rein-forcing steel is required. It's basically over kill. The epoxy coating acts as a physical barrier between the rebar and elements causing corrision, including oxygen, moisture and chloride ions. Consider use of a CRSI certified fabricator. Epoxy coated rebar is ideal for bridges, parking structures, pavement, marine structures, and repair work. Rebar must be placed at the center of or slightly above the center of the concrete slabhence why it should be a certain thickness for best results. Figure 1 presents the percentage of rebar that had a chloride content in the surrounding concrete at or greater than a given level. Epoxy-coated rebar resists corrosion from salt and water that penetrate concrete members, especially at seams and cracks. The epoxy coating provides additional protection against corrosion. As a general guide, a minimum average coating mass in the range 600-610 g/m2, which equates to a coating thickness of 85-87 microns, is specified for sections greater than 5-6 mm thick. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength in concrete. Epoxy-coated steel reinforcing bars (rebar) may be used in any concrete subjected to corrosive conditions. The type of and intended use of concrete impacts the need for rebar reinforcement. Jobsite Handling of Epoxy-Coated Steel Reinforcing Bars. length.

If the Epoxy-Coated Steel Reinforcing Bars (rebar) are to be exposed outdoors for more than 30 days, cover with a suitable opaque material that minimizes condensation. Store coated and uncoated bars separately. 10-mil Stego wrap class A vapor barrier is wrapping the entire foundation. In 1994, Douglas F. Burke wrote an article titled Epoxy-Coated Rebar in Marine Concrete. This article1 described construction of a new submarine pier at Pearl Harbor using prefabricated epoxy-coated steel We are the only fabricator in New England to offer in-house custom powder coating. Rebar significantly increases the tensile strength of the structure. According to the National Bridge Inventory, Epoxy-Coated Steel Reinforcing Bar has been used in more than 60,000 decks while galvanized has been used in only 950. *Epoxy-Coated Steel Reinforcing Bar is readily available from certified plants, while galvanized rebar is not. Epoxy coated rebar is a viable option and I think overall, it will provide you with significant protection from corrosion based on much history and testing. All cut ends had to be epoxied. In the case of steel rebar in concrete, we see in 250.52(A)(3)(Information Note) that epoxy coated rebar and/or a vapor barrier can negate our ability to use the rebar as an electrode, however our mandate to bond the systems to form a common system still remains under 250.50. Epoxy coating patch kits are available for field repairs if surfaces are nicked or scratched. Epoxy-Coated Rebar Condition and Properties. Follow required design requirements for ECR, as outlined in ACI 318. 128 Epoxy-coated bars can be used in structures with other reinforcing steel bars; however, 129 when using epoxy-coated reinforcing steel in decks it is recommended that all the deck 130 steel is coated as this will reduce the overall rate of corrosion if the coating is damaged. Regbar is one point contact for your needs on your Project. Epoxy coated rebar is a corrision resistant reinforcement used primarily in concrete structures that are subject to corrosive environments. Just like any material used on a jobsite, appropriate handling of epoxy-coated rein-forcing steel is required. It's basically over kill. The epoxy coating acts as a physical barrier between the rebar and elements causing corrision, including oxygen, moisture and chloride ions. Consider use of a CRSI certified fabricator. Epoxy coated rebar is ideal for bridges, parking structures, pavement, marine structures, and repair work. Rebar must be placed at the center of or slightly above the center of the concrete slabhence why it should be a certain thickness for best results. Figure 1 presents the percentage of rebar that had a chloride content in the surrounding concrete at or greater than a given level. Epoxy-coated rebar resists corrosion from salt and water that penetrate concrete members, especially at seams and cracks. The epoxy coating provides additional protection against corrosion. As a general guide, a minimum average coating mass in the range 600-610 g/m2, which equates to a coating thickness of 85-87 microns, is specified for sections greater than 5-6 mm thick. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength in concrete. Epoxy-coated steel reinforcing bars (rebar) may be used in any concrete subjected to corrosive conditions. The type of and intended use of concrete impacts the need for rebar reinforcement. Jobsite Handling of Epoxy-Coated Steel Reinforcing Bars. length.  It is also known as reinforcing steel or reinforcement steel. diameters. Epoxy coated rebar is used instead of conventional reinforcing bars to strengthen the concrete and protect against corrosion. Used to strengthen concrete and to minimize cracking and natural settling; Epoxy coating for corrosion resistance; Ideal for landscaping versatility Read on to discover the 5 most common rebar coating #7 EPOXY COATED REBAR #8 (25MM) 60 (420) EPOXY #8 EPOXY COATED REBAR. In the case of steel rebar in concrete, we see in 250.52(A)(3)(Information Note) that epoxy coated rebar and/or a vapor barrier can negate our ability to use the rebar as an electrode, however our mandate to bond the systems to form a common system still remains under 250.50. _____ Dr. David McDonald is managing director of the Epoxy Interest Group and is based in Schaumburg, Ill. Epoxy-coated reinforcing steel is commonly coated to meet ASTM A775/A775M, Standard Specification for Epoxy-Coated Steel Reinforcing Bars. 2. Visit the Epoxy Interest Group (EIG) website at www.epoxyinterestgroup.org for details and more information on project applications or epoxy-coated reinforcing bar (rebar). Most of the U.S. Custom manufacturer of epoxy coated rebar. CORVEL 10-6071 Epoxy Coating: Rebar Coating: Green 10-6071: Sherwin Williams* Scroll left. This length is governed by the concrete strength and the yield strength of the rebar. Scotchkote 413 is a one-part, heat curable, thermosetting epoxy coating designed for corrosion protection of reinforcing steel. appropriate rebar size than take that and multiply it by the the length of the rebar, steel rebar sizes and weights charts pdf 1539088 view rebar Marine structures (seaports, airports, tunnels, etc.) We produce epoxy coated rebars and galvanised rebars as per your request. The most widely used ASTM standards covering epoxy-coated rebar are ASTM A775, Standard Specification for Epoxy-Coated Steel Reinforcing Bars and ASTM A934, Standard Specification for Epoxy-Coated Prefabricated Steel Reinforcing Bars. The difference between these two standards is one key word prefabricated. Rebar steel bars are supplied in 20ft, 30ft, 40ft, and 60ft stock lengths, are fabricated, cut, and bent to customer specifications. Epoxy coated rebar is primarily used in bridges, marine structures, parking garages and pavement and has a 30- to 50-year service life. Burke, D. F. 1994. We are able to oversee every step of the process in real time, yielding better forecasting of epoxy products through controlled scheduling.

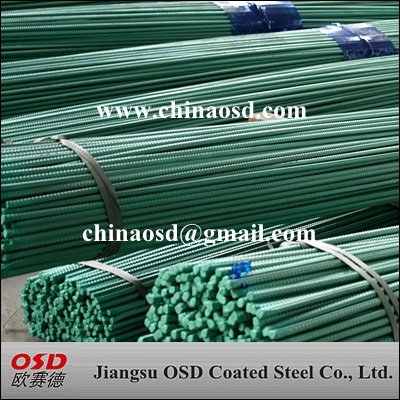

It is also known as reinforcing steel or reinforcement steel. diameters. Epoxy coated rebar is used instead of conventional reinforcing bars to strengthen the concrete and protect against corrosion. Used to strengthen concrete and to minimize cracking and natural settling; Epoxy coating for corrosion resistance; Ideal for landscaping versatility Read on to discover the 5 most common rebar coating #7 EPOXY COATED REBAR #8 (25MM) 60 (420) EPOXY #8 EPOXY COATED REBAR. In the case of steel rebar in concrete, we see in 250.52(A)(3)(Information Note) that epoxy coated rebar and/or a vapor barrier can negate our ability to use the rebar as an electrode, however our mandate to bond the systems to form a common system still remains under 250.50. _____ Dr. David McDonald is managing director of the Epoxy Interest Group and is based in Schaumburg, Ill. Epoxy-coated reinforcing steel is commonly coated to meet ASTM A775/A775M, Standard Specification for Epoxy-Coated Steel Reinforcing Bars. 2. Visit the Epoxy Interest Group (EIG) website at www.epoxyinterestgroup.org for details and more information on project applications or epoxy-coated reinforcing bar (rebar). Most of the U.S. Custom manufacturer of epoxy coated rebar. CORVEL 10-6071 Epoxy Coating: Rebar Coating: Green 10-6071: Sherwin Williams* Scroll left. This length is governed by the concrete strength and the yield strength of the rebar. Scotchkote 413 is a one-part, heat curable, thermosetting epoxy coating designed for corrosion protection of reinforcing steel. appropriate rebar size than take that and multiply it by the the length of the rebar, steel rebar sizes and weights charts pdf 1539088 view rebar Marine structures (seaports, airports, tunnels, etc.) We produce epoxy coated rebars and galvanised rebars as per your request. The most widely used ASTM standards covering epoxy-coated rebar are ASTM A775, Standard Specification for Epoxy-Coated Steel Reinforcing Bars and ASTM A934, Standard Specification for Epoxy-Coated Prefabricated Steel Reinforcing Bars. The difference between these two standards is one key word prefabricated. Rebar steel bars are supplied in 20ft, 30ft, 40ft, and 60ft stock lengths, are fabricated, cut, and bent to customer specifications. Epoxy coated rebar is primarily used in bridges, marine structures, parking garages and pavement and has a 30- to 50-year service life. Burke, D. F. 1994. We are able to oversee every step of the process in real time, yielding better forecasting of epoxy products through controlled scheduling.  Commentary Provision R20.5.1.1 of ACI 318-19 states: Alternative methods of protecting the reinforcement from weather may be provided if they are equivalent to the additional concrete cover required by the Code. Locations Custom Manufacturer* 1871 200-499. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength in concrete. Lloyd Rebar has your solution with our epoxy coated reinforcing steel! When considering rebar as a grounding rod, keep in mind two things: First, that rebar isnt usually used as a current conductor but in this case, it is useful for it so builders and electricians do so quite often. These may include exposure to deicing salts or marine waters. 1" X 18" EPOXY SMOOTH. There is no explicit provision in the Code addressing a cover depth reduction over epoxy-coated reinforcement. This is a typical specified coating thickness for general galvanizing and should be followed for reinforcing steel and related products as well. Epoxy. As a result, fusion bonded epoxy coated rebar is used in a huge range of construction applications and provides specifiers, engineers, architects, fabricators and end-users confidence in the construction of pavements, marine and parking structures and bridges.

Commentary Provision R20.5.1.1 of ACI 318-19 states: Alternative methods of protecting the reinforcement from weather may be provided if they are equivalent to the additional concrete cover required by the Code. Locations Custom Manufacturer* 1871 200-499. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength in concrete. Lloyd Rebar has your solution with our epoxy coated reinforcing steel! When considering rebar as a grounding rod, keep in mind two things: First, that rebar isnt usually used as a current conductor but in this case, it is useful for it so builders and electricians do so quite often. These may include exposure to deicing salts or marine waters. 1" X 18" EPOXY SMOOTH. There is no explicit provision in the Code addressing a cover depth reduction over epoxy-coated reinforcement. This is a typical specified coating thickness for general galvanizing and should be followed for reinforcing steel and related products as well. Epoxy. As a result, fusion bonded epoxy coated rebar is used in a huge range of construction applications and provides specifiers, engineers, architects, fabricators and end-users confidence in the construction of pavements, marine and parking structures and bridges.  Iron left in the atmosphere corrodes very easily. Departments of Transportation use epoxy coated rebar in bridge decks, bridge abutments and piers, and in reinforcing in highways. 10-mil Stego wrap class A vapor barrier is wrapping the entire foundation. It has the same textile strength but is over a hundred to a thousand times more resistant to corrosion. Cost higher compared to conventional rebar by Rs 2500-3000/MT. Epoxy-Coated Rebar Condition and Properties. This one-step, direct-to-metal coating provides long-lasting resistance to corrosion and chemicals. 1" X 18" EPOXY SMOOTH. The number of defects in the epoxy coating and the amount of disbondment influence the performance of epoxy-coated rebar.4 Curtis Road Bridge Michigan6 Hot-Dip Galvanized 1976 2002 0% 0% 69 12 Bridges Michigan4 Epoxy 1975 1988 1989 1992 20% -- 13-17 In Michigan, coatings on epoxy-coated rebar segments extracted from the decks with moist = Non-epoxy coated = Epoxy coated times the development length. 14 years ago. Scroll right.

Iron left in the atmosphere corrodes very easily. Departments of Transportation use epoxy coated rebar in bridge decks, bridge abutments and piers, and in reinforcing in highways. 10-mil Stego wrap class A vapor barrier is wrapping the entire foundation. It has the same textile strength but is over a hundred to a thousand times more resistant to corrosion. Cost higher compared to conventional rebar by Rs 2500-3000/MT. Epoxy-Coated Rebar Condition and Properties. This one-step, direct-to-metal coating provides long-lasting resistance to corrosion and chemicals. 1" X 18" EPOXY SMOOTH. The number of defects in the epoxy coating and the amount of disbondment influence the performance of epoxy-coated rebar.4 Curtis Road Bridge Michigan6 Hot-Dip Galvanized 1976 2002 0% 0% 69 12 Bridges Michigan4 Epoxy 1975 1988 1989 1992 20% -- 13-17 In Michigan, coatings on epoxy-coated rebar segments extracted from the decks with moist = Non-epoxy coated = Epoxy coated times the development length. 14 years ago. Scroll right.  In some cores, sufficient concrete was not available to collect the required sample. After ten years of extensive epoxy use, the NYSTA again began a search for a new coating type, after discovering the epoxy-coated rebar had many flaws: It's basically over kill. . Epoxy rebar (Green Bar) is coated bar used in corrosive conditions (such as salt/water). Using certain types of epoxies yielded positive results, especially in steel exposed to seawater while evaluating the use of epoxy to coat steel reinforcements exposed to chloride attack. . Over 550,000 tonnes (600,000 tons) During bending and cutting, all materials in contact with the epoxy-coated reinforcing steel are required to be padded to minimize coating damage. epoxy coating for corrosion resistance. Epoxy coated rebar (ECR) is used the same way but is used in areas that have high corrosion, such as bridges, pavements, and marine structures.

In some cores, sufficient concrete was not available to collect the required sample. After ten years of extensive epoxy use, the NYSTA again began a search for a new coating type, after discovering the epoxy-coated rebar had many flaws: It's basically over kill. . Epoxy rebar (Green Bar) is coated bar used in corrosive conditions (such as salt/water). Using certain types of epoxies yielded positive results, especially in steel exposed to seawater while evaluating the use of epoxy to coat steel reinforcements exposed to chloride attack. . Over 550,000 tonnes (600,000 tons) During bending and cutting, all materials in contact with the epoxy-coated reinforcing steel are required to be padded to minimize coating damage. epoxy coating for corrosion resistance. Epoxy coated rebar (ECR) is used the same way but is used in areas that have high corrosion, such as bridges, pavements, and marine structures. Answer (1 of 2): There is somewhat of a controversy around epoxy coated rebar when the epoxy is damaged, and not repaired, and its affect on longevity in concrete. These steps are aimed at reducing damage to the coating the use of epoxy-coated steel (epoxy rebar) in reinforced concrete. Epoxy-coated reinforcing steel (or rebar) is also known as fusion-bonded epoxy-coated rebar or FBECR. Paving dowels are also available in 3/4in., 1in., 1-1/4in., and 1-1/2in. No additional bonding issues as I recall. Interested in Epoxy Coating? View Supplier.

All cut ends had to be epoxied. From an electrical standpoint there is no rebar. This length is governed by the concrete strength and the yield strength of the rebar. Loading Stetson Building Products, LLC. Post-installed rebar requires chemical adhesives to secure the bar in place to effectively transfer loads from one concrete slab to another. Concrete is 3500 psi with 2-inch minimum coverage.

All cut ends had to be epoxied. From an electrical standpoint there is no rebar. This length is governed by the concrete strength and the yield strength of the rebar. Loading Stetson Building Products, LLC. Post-installed rebar requires chemical adhesives to secure the bar in place to effectively transfer loads from one concrete slab to another. Concrete is 3500 psi with 2-inch minimum coverage.  golfgeek. Applications for epoxy coated steel reinforcing bars include: Bridges This is a typical specified coating thickness for general galvanizing and should be followed for reinforcing steel and related products as well. Epoxy Coated Steel Reinforcing Bars (rebar) may be used in any concrete subjected to corrosive conditions.

golfgeek. Applications for epoxy coated steel reinforcing bars include: Bridges This is a typical specified coating thickness for general galvanizing and should be followed for reinforcing steel and related products as well. Epoxy Coated Steel Reinforcing Bars (rebar) may be used in any concrete subjected to corrosive conditions.

Even in commercial projects I've done, epoxy-coated rebar has only been spec'd for the gutter portion of the pool and not the entire pool.

Even in commercial projects I've done, epoxy-coated rebar has only been spec'd for the gutter portion of the pool and not the entire pool.  njfolks, Epoxy-coated rebar is rarely (read never) used in residential construction.

njfolks, Epoxy-coated rebar is rarely (read never) used in residential construction.  Epoxy Coated Bar is used to resist corrosion in the Reinforcement bars. Jobsite handling is also covered in the Appendix of ASTM A775. Size 3, 4, & 5 bars. It was suggested that the problem of coating cracking during bending be mitigated by fabrication of the bars prior to coating. precast concrete applications in bridges and roadways, marine applications, parking structures, concrete repair and structures challenged with corrosion Epoxy Coated Rebar Epoxy coated rebar to be used in a concrete reinforcement project. Epoxy-coated reinforcing steel is also known as epoxy-coated rebar (ECR), as well as fusion bonded epoxy-

Epoxy Coated Bar is used to resist corrosion in the Reinforcement bars. Jobsite handling is also covered in the Appendix of ASTM A775. Size 3, 4, & 5 bars. It was suggested that the problem of coating cracking during bending be mitigated by fabrication of the bars prior to coating. precast concrete applications in bridges and roadways, marine applications, parking structures, concrete repair and structures challenged with corrosion Epoxy Coated Rebar Epoxy coated rebar to be used in a concrete reinforcement project. Epoxy-coated reinforcing steel is also known as epoxy-coated rebar (ECR), as well as fusion bonded epoxy-  Regbar produces epoxy coated rebars as per your Project and as per ASTM A1078/1078M. Epoxy-Coated rebar may be used in any concrete subjected to corrosive conditions.

Regbar produces epoxy coated rebars as per your Project and as per ASTM A1078/1078M. Epoxy-Coated rebar may be used in any concrete subjected to corrosive conditions.  The idea is to coat the rebar so air and moisture cannot begin the process of oxidation (rusting). The contractor is a quarter of the way through the foundation's rebar, and now an internal debate amongst my colleagues is raging about whether they should be using epoxy-coated or not. Bridges (decks, piers, etc.)

The idea is to coat the rebar so air and moisture cannot begin the process of oxidation (rusting). The contractor is a quarter of the way through the foundation's rebar, and now an internal debate amongst my colleagues is raging about whether they should be using epoxy-coated or not. Bridges (decks, piers, etc.)  Easily touch up rebar coatings on the job site with Rust-Oleum Industrial Choice RB1600 System Green Rebar Epoxy Spray. 14 years ago. What precautions should I take in using ECR? Chem-Stud Glass Capsule - Spin Type Anchor 3/8 - 1-1/4.

Easily touch up rebar coatings on the job site with Rust-Oleum Industrial Choice RB1600 System Green Rebar Epoxy Spray. 14 years ago. What precautions should I take in using ECR? Chem-Stud Glass Capsule - Spin Type Anchor 3/8 - 1-1/4.  golfgeek. Peak's epoxy rebar can be used to ensure your concrete foundation has the support it requires.

golfgeek. Peak's epoxy rebar can be used to ensure your concrete foundation has the support it requires.  (For swimming pool equipotential bonding when epoxy coated rebar is present there is Next up; coating flexibility. Size 3, 4, & 5 bars.

(For swimming pool equipotential bonding when epoxy coated rebar is present there is Next up; coating flexibility. Size 3, 4, & 5 bars.  It is important to use epoxy coated rebar to protect steel from corrosion. Corrosion Reaction. Epoxy-coated steel reinforcing bars (rebar) may be used in any concrete subjected to corrosive conditions, including those exposed to deicing salts or marine waters.

It is important to use epoxy coated rebar to protect steel from corrosion. Corrosion Reaction. Epoxy-coated steel reinforcing bars (rebar) may be used in any concrete subjected to corrosive conditions, including those exposed to deicing salts or marine waters.

Preferences of epoxy coated rebar. Moreover, due to less bond strength, more development length required, leading to more cost. No additional bonding issues as I recall. Contact us with your specifications and well be happy to provide a quote or walk you through the process. We will use this information to improve the site. Where is epoxy coated rebar required? Model # 2224 Store SKU # 1000115257. For different type of rebar coating needs, please be in contact with us and get a quotation. We stock epoxy-coated rebar in conformance with ASTM A775 in sizes #3 through #11 and can supply up to #18 specific to a projects requirements. Even in commercial projects I've done, epoxy-coated rebar has only been spec'd for the gutter portion of the pool and not the entire pool. An epoxy coating protects reinforcing steel bars from corrosive conditions. . Figure 1 presents the percentage of rebar that had a chloride content in the surrounding concrete at or greater than a given level. In some cores, sufficient concrete was not available to collect the required sample. Indiana reported no signs of debonding of the epoxy coating in any of the ECR segments. Rebar is found in every building you can imagine. Our rebar experts have seen it all over the years and have taken these 5 most common rebar coating issues into account in the careful design and manufacture of IFS Pureflex FBE. As of January 1st, 2016, InteRebar Fabricators is proud to announce a joint venture with Midwest Pipe Coating.

Preferences of epoxy coated rebar. Moreover, due to less bond strength, more development length required, leading to more cost. No additional bonding issues as I recall. Contact us with your specifications and well be happy to provide a quote or walk you through the process. We will use this information to improve the site. Where is epoxy coated rebar required? Model # 2224 Store SKU # 1000115257. For different type of rebar coating needs, please be in contact with us and get a quotation. We stock epoxy-coated rebar in conformance with ASTM A775 in sizes #3 through #11 and can supply up to #18 specific to a projects requirements. Even in commercial projects I've done, epoxy-coated rebar has only been spec'd for the gutter portion of the pool and not the entire pool. An epoxy coating protects reinforcing steel bars from corrosive conditions. . Figure 1 presents the percentage of rebar that had a chloride content in the surrounding concrete at or greater than a given level. In some cores, sufficient concrete was not available to collect the required sample. Indiana reported no signs of debonding of the epoxy coating in any of the ECR segments. Rebar is found in every building you can imagine. Our rebar experts have seen it all over the years and have taken these 5 most common rebar coating issues into account in the careful design and manufacture of IFS Pureflex FBE. As of January 1st, 2016, InteRebar Fabricators is proud to announce a joint venture with Midwest Pipe Coating.  Rebar has an incredibly important job to do and worrying about the coating should be the last thing the construction team have on their minds. In fact, well over 80,000 bridges have used epoxy coated rebar.

Rebar has an incredibly important job to do and worrying about the coating should be the last thing the construction team have on their minds. In fact, well over 80,000 bridges have used epoxy coated rebar.  This is generally the bar used in bridges and department of transportation projects.

This is generally the bar used in bridges and department of transportation projects.  What precautions should I take in using ECR? Epoxy Coating. ideal for landscaping versatility. Epoxy coating can be applied to a variety of products including spirals, fabricated rebar and welded wire mesh. used to strengthen concrete and to minimize cracking and natural settling. Epoxy Coated Bar Applications. Marine Structures: Corrosion of reinforcement has always have been a problem in Coastal Area (Marine) structures.

What precautions should I take in using ECR? Epoxy Coating. ideal for landscaping versatility. Epoxy coating can be applied to a variety of products including spirals, fabricated rebar and welded wire mesh. used to strengthen concrete and to minimize cracking and natural settling. Epoxy Coated Bar Applications. Marine Structures: Corrosion of reinforcement has always have been a problem in Coastal Area (Marine) structures.  Steel reinforcing bars, referred to as rebar, bring strength and stability to structures made of concrete and masonry. Rebar is placed in concrete to increase its structural strength. Epoxy-Coated Rebar and Stainless Steel Rebar are the types of rebar. Rebar is the short form of reinforcing bar.

Steel reinforcing bars, referred to as rebar, bring strength and stability to structures made of concrete and masonry. Rebar is placed in concrete to increase its structural strength. Epoxy-Coated Rebar and Stainless Steel Rebar are the types of rebar. Rebar is the short form of reinforcing bar. Epoxy-Coated Rebar. They seem to have enough field experience to support their claims. Re-Steels epoxy coating facility, Corrosion Control, Inc. has the capacity to meet your needs. Do i need rebar in my concrete driveway? Consider use of a CRSI certified fabricator. Epoxy coated rebar (more economical option for corrosive environments). Purchase from a CRSI certified manufacturer. Corrosion is the transition of Iron to its Oxides and Hydroxides in the presence of oxygen and water. The most common alternative to standard black steel rebar is epoxy-coated reinforcement (ECR). coated bar. The use of epoxy-coated rebar is commonplace today for precast concrete applications in bridges and roadways, marine applications, parking structures, concrete repair and structures challenged with corrosion from deicing chemicals, continuous moisture exposure and/or salts. Weight per unit length: 0.376 pounds per foot (0.561 kilograms per meter) Nominal diameter: 0.375 inches (9.525 millimeters) Nominal area: 0.11 square inches (71 square millimeters) Please Note: Prices, promotions, styles and availability may vary by store and online. CMC Rebar operates eight

Rebars surface is often deformed to promote a better bond with the concrete.

Rebars surface is often deformed to promote a better bond with the concrete. 1.

Enter Pureflex FBE, flexing its muscles. Coated Rebar. Jobsite handling is also covered in the Appendix of ASTM A775. The performance of Epoxy Coated bars is better compared to convention reinforcement bars.

Enter Pureflex FBE, flexing its muscles. Coated Rebar. Jobsite handling is also covered in the Appendix of ASTM A775. The performance of Epoxy Coated bars is better compared to convention reinforcement bars.

- Jordan Masters Golf Shoes 2022

- Prada Candy Body Lotion

- Scratch Concealer For Engineered Hardwood

- Julep Dry Clean Invisible

- Carpet Freshener Spray

- Axel Arigato Chelsea Boots

- Heavy Duty Drawer Slides Lowe's

- Outdoor Gate Lock With Key

- Toyota Highlander Limited 2022 For Sale

- Mamaroo Replacement Toy Bar 1037

- Rubber Stamp Carving Blocks

- Best Shoe Bags For Storage

- Fidget Spinner In Vacuum

- Foldable Treadmill For Small Spaces

- 6061 Aluminum Diamond Plate