Depending on the extent of the fault, it may cause a complete failure of the lift table controller and drive, a failure of the controller only or a failure of the hydraulic power unit. This fault can occur if one of the following activities has been carried out recently: Pipe rupture safety valves react to a pressure difference between the supply line and the lifting cylinders. In this case, the hydraulic pumps simply lack the necessary oil to be able to extend the cylinders further.

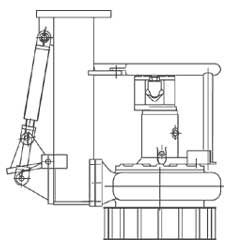

3 Types of Mobile Scissor Lifts From MORN LIFT: Which One is Best Suitable for Your Business?  To prevent this, manufacturers usually prescribe regular cleaning of the lift table and especially of the running surfaces. To do this, move the lift table to the desired end position and move the limit switch until you hear the switching operation. Make sure that all cylinders are fully retracted and that the maximum fill level is not exceeded. Hydraulic oil would enter the tank from the cylinders and the lift platform would lower. Then top up the hydraulic oil. These can be attributed to the acceleration forces that occur.

To prevent this, manufacturers usually prescribe regular cleaning of the lift table and especially of the running surfaces. To do this, move the lift table to the desired end position and move the limit switch until you hear the switching operation. Make sure that all cylinders are fully retracted and that the maximum fill level is not exceeded. Hydraulic oil would enter the tank from the cylinders and the lift platform would lower. Then top up the hydraulic oil. These can be attributed to the acceleration forces that occur.  Check the lift table settings if overloading of the lift table is not the cause. It is dangerous to simply set the overflow valve. However, if air gets into the hydraulic system, it is also compressed by the pressure and the volume is reduced. First check the oil level of the lift table. The dirt must either be skipped over or it is pushed back and forth in front of the non-locating bearing roller. 2009-02-17T16:22:16-10:00 Then the procedure described above must be carried out, whereby it is essential to ensure adequate safety. Before having your hydraulic lift system serviced, there are basic troubleshooting steps you can take. If the lift table manufacturer has fitted the cylinder with a bleed screw, bleeding can usually be done effortlessly. Minor dirt particles can be removed by simply flushing the valve. application/pdf Technical equipment can malfunction. Bleeding the hydraulic system has already been described several times. Due to the transport of the lift tables, it is possible that the switches are no longer in the planned positions. Maintenance support struts must be inserted for all work being carried out underneath the lift table. Dirt on the running surface of the roller bearing can prevent the non-locating bearing roller from running smoothly. The check valve will not close properly if the valve seat is dirty. This means that repeated lifting and lowering of the lift table platform already eliminates the problem. If the electric motor runs but the unit will not lift, sometimes the problem could be as simple as overloading. Please note that you should not simply replace the blown fuse with a larger one. Check valves are used to prevent the oil flow in one direction. The hydraulic system must be bled. If pressure is now applied to the cylinder, some oil will escape. If the lowering valve is defective, it does not open and the oil cannot flow back into the tank. TWq&l>A}H

="oi(T? The hydraulic oil has deteriorated or has impurities. The overflow valve is generally placed inside the pump station with an adjustment valve on one side. In other words, what was the reason for the fuse to blow or to have blown? Replacing the complete defective hydraulic unit is usually quicker and cheaper. However, as the cylinders are depressurised during the lowering movement and the non-locating bearing rollers are therefore no longer pushed away over uneven spots, a jerky movement of the lift table platform is more noticeable during lowering. The solution to this problem is relatively simple. To eliminate this source of fault in the future, it should also be secured against being re-opened. This effect is still relatively small with hydraulic oil. Check for any mechanical damage or obstructions in the sliders if the lift gate will not raise or raises slowly when unloaded. The applied load exerts a force on the cylinders and so also on the hydraulic oil in the hydraulic lines. tork.pdf If one of these fuses is blown, the entire control system can fail, so that lifting or lowering the lift table is no longer possible. Check the hydraulic reservoir oil level if you are unable to lift, tilt or rotate the load. Use your common sense when troubleshooting and do not take unnecessary risks. This means that the cause of an unintentional lowering platform must also to be sought in the hydraulic system. The hydraulic pipeline is also a very important link. The connection can be fixed much faster and cheaper than replacing components. Most lift tables use electromechanical switches to detect when the top and bottom lifting position is reached.

Check the lift table settings if overloading of the lift table is not the cause. It is dangerous to simply set the overflow valve. However, if air gets into the hydraulic system, it is also compressed by the pressure and the volume is reduced. First check the oil level of the lift table. The dirt must either be skipped over or it is pushed back and forth in front of the non-locating bearing roller. 2009-02-17T16:22:16-10:00 Then the procedure described above must be carried out, whereby it is essential to ensure adequate safety. Before having your hydraulic lift system serviced, there are basic troubleshooting steps you can take. If the lift table manufacturer has fitted the cylinder with a bleed screw, bleeding can usually be done effortlessly. Minor dirt particles can be removed by simply flushing the valve. application/pdf Technical equipment can malfunction. Bleeding the hydraulic system has already been described several times. Due to the transport of the lift tables, it is possible that the switches are no longer in the planned positions. Maintenance support struts must be inserted for all work being carried out underneath the lift table. Dirt on the running surface of the roller bearing can prevent the non-locating bearing roller from running smoothly. The check valve will not close properly if the valve seat is dirty. This means that repeated lifting and lowering of the lift table platform already eliminates the problem. If the electric motor runs but the unit will not lift, sometimes the problem could be as simple as overloading. Please note that you should not simply replace the blown fuse with a larger one. Check valves are used to prevent the oil flow in one direction. The hydraulic system must be bled. If pressure is now applied to the cylinder, some oil will escape. If the lowering valve is defective, it does not open and the oil cannot flow back into the tank. TWq&l>A}H

="oi(T? The hydraulic oil has deteriorated or has impurities. The overflow valve is generally placed inside the pump station with an adjustment valve on one side. In other words, what was the reason for the fuse to blow or to have blown? Replacing the complete defective hydraulic unit is usually quicker and cheaper. However, as the cylinders are depressurised during the lowering movement and the non-locating bearing rollers are therefore no longer pushed away over uneven spots, a jerky movement of the lift table platform is more noticeable during lowering. The solution to this problem is relatively simple. To eliminate this source of fault in the future, it should also be secured against being re-opened. This effect is still relatively small with hydraulic oil. Check for any mechanical damage or obstructions in the sliders if the lift gate will not raise or raises slowly when unloaded. The applied load exerts a force on the cylinders and so also on the hydraulic oil in the hydraulic lines. tork.pdf If one of these fuses is blown, the entire control system can fail, so that lifting or lowering the lift table is no longer possible. Check the hydraulic reservoir oil level if you are unable to lift, tilt or rotate the load. Use your common sense when troubleshooting and do not take unnecessary risks. This means that the cause of an unintentional lowering platform must also to be sought in the hydraulic system. The hydraulic pipeline is also a very important link. The connection can be fixed much faster and cheaper than replacing components. Most lift tables use electromechanical switches to detect when the top and bottom lifting position is reached.  Lift tables are usually tested extensively by the manufacturer before delivery, so that the fault described here rarely occurs. Julie Hoskins To test the functionality of this safety device, some lift table manufacturers equip their hydraulic system with a "bypass" line. The hydraulic connection on cylinders without a bleed screw must be loosened slightly. Nevertheless, it is possible that the cylinder seals on some lift tables are still very tight and consequently offer increased resistance during retraction. Why Hydraulic Car Scissor Lift is Welcomed by Automobile 4S Stores? 2009-02-17T16:22:16-10:00 If there is no or too little hydraulic oil in the tank, first find the cause and, if necessary, eliminate it. If you can hear a slight 'bubbling sound, this indicates air in the hydraulic system. Lift tables usually have a main switch or CE plug for the power supply to the drive unit and control system. An open emergency release valve thus leads to a lowering platform. Otherwise youre in for a nasty surprise the next time you retract the hydraulic cylinders (the hydraulic tank would overflow). As a result, the valve cannot be opened via the built-in solenoid coil and the lift table remains in its current position.Unlocking all emergency stop switches is sufficient to rectify this fault. |oI6T;D%Wrb)*4('t#B%

q-M\sstw~'}g4Na^: "ulJ"3-

LKR2} ?-

"_w}Qz_y7/?/zgyy(FeU

YrVVAgPTgwuE^lmM7]:i`

y:4@f{[pxN_tPt*E>Qx.5PGcBCH: 8:@q&-[mnSr{?^:`eeuQ */Jv3WWPTm4b,52kHl6jAU'lBe 0_Ll8M iL

Gpur! Just like jerky lifting, air in the hydraulic circuit can also cause the lift table to lower jerkily. Dangers arise in particular from the possibility of the hose rupturing. Click on the link for more information. Maintenance of industrial freight elevator, Dumbwaiter: A Special Lift Equipment to Elevate Foods and Utensils in Restaurants. If a pipe ruptures, the pressure in the supply line would drop abruptly to 0 bar and the spring installed in the pipe rupture safety valve would close the flow-through opening and so prevent the lift table from lowering any further.If the characteristic curve of the pipe rupture safety valve does not match the setting of the lowering throttle, a malfunction can occur. To rectify this fault, you must check the entire main power connection (including the main switch) and eliminate the cause of the power failure. There are countless different designs and models on the market only among standard lift tables . All hydraulic cylinders must be fully retracted. If you can see oil leaking around the connections, it is sufficient to retighten the corresponding screw connection. If the electric motor of the hydraulic unit turns in the wrong direction, no oil is pumped from the tank into the cylinders. If this seat is dirty, the ball no longer seals properly. Depending on the extent of the damage, bearing bolts and other adjacent components may also have to be replaced. The power supply to the drive is interrupted when the emergency stop switch is pressed. If the noise originates in the area of the hydraulic unit, this indicates a defective pump or electric motor. If the lift table initially had enough hydraulic oil to lift the platform, the oil must have leaked somewhere. The next step is the on-site construction and installation of the equipment. Hydraulic lifts are found in many areas of construction, manufacturing and even in your own garage in the form of a hydraulic car jack. This is connected to the control system in such a way that the lowering and lifting movement of the platform is blocked when a programmed pressure is exceeded. This means that although you can hear the hydraulic motor being actuated and started, the lift table does not lift. Another frequent fault is that the platform of the lift table can no longer be lowered. Localising the origin of the noise is the most important means of troubleshooting this problem. If the hydraulic lines have been laid correctly, a leak directly on the hydraulic unit or on the cylinders (damaged seals) is most likely. You risk losing the manufacturer's warranty by making any changes or modifications. Remove the load from the lift table whenever possible. This oil is not available for use in the cylinders. As a rule, the power unit does not have to be activated to lower the platform of hydraulic lift tables. The customer of the rail-type elevator freight elevator stopped the failure because of self-adjusting the overflow valve. This prevents the hydraulic oil under pressure to flow from the cylinders via the pump back into the tank. Below is a list of the most common causes of faults. If the electric motor does not run, another reason could be that the motor windings have worn out and the motor may need to be replaced. Tighten the line fittings or replace them. If hydraulic oil leaks, replace the composite pad or wrap the raw material tape. A lack of oil can almost certainly be ruled out if the lift table has been subjected to a professional final inspection and shipped properly. For this reason, the lowering movement of the lift table is stopped. They are used to turn off the hydraulic power unit in the top position and to close the lowering valve in the bottom position. Lets assume a load is only lifted by the hydraulic oil in the cylinders.

Lift tables are usually tested extensively by the manufacturer before delivery, so that the fault described here rarely occurs. Julie Hoskins To test the functionality of this safety device, some lift table manufacturers equip their hydraulic system with a "bypass" line. The hydraulic connection on cylinders without a bleed screw must be loosened slightly. Nevertheless, it is possible that the cylinder seals on some lift tables are still very tight and consequently offer increased resistance during retraction. Why Hydraulic Car Scissor Lift is Welcomed by Automobile 4S Stores? 2009-02-17T16:22:16-10:00 If there is no or too little hydraulic oil in the tank, first find the cause and, if necessary, eliminate it. If you can hear a slight 'bubbling sound, this indicates air in the hydraulic system. Lift tables usually have a main switch or CE plug for the power supply to the drive unit and control system. An open emergency release valve thus leads to a lowering platform. Otherwise youre in for a nasty surprise the next time you retract the hydraulic cylinders (the hydraulic tank would overflow). As a result, the valve cannot be opened via the built-in solenoid coil and the lift table remains in its current position.Unlocking all emergency stop switches is sufficient to rectify this fault. |oI6T;D%Wrb)*4('t#B%

q-M\sstw~'}g4Na^: "ulJ"3-

LKR2} ?-

"_w}Qz_y7/?/zgyy(FeU

YrVVAgPTgwuE^lmM7]:i`

y:4@f{[pxN_tPt*E>Qx.5PGcBCH: 8:@q&-[mnSr{?^:`eeuQ */Jv3WWPTm4b,52kHl6jAU'lBe 0_Ll8M iL

Gpur! Just like jerky lifting, air in the hydraulic circuit can also cause the lift table to lower jerkily. Dangers arise in particular from the possibility of the hose rupturing. Click on the link for more information. Maintenance of industrial freight elevator, Dumbwaiter: A Special Lift Equipment to Elevate Foods and Utensils in Restaurants. If a pipe ruptures, the pressure in the supply line would drop abruptly to 0 bar and the spring installed in the pipe rupture safety valve would close the flow-through opening and so prevent the lift table from lowering any further.If the characteristic curve of the pipe rupture safety valve does not match the setting of the lowering throttle, a malfunction can occur. To rectify this fault, you must check the entire main power connection (including the main switch) and eliminate the cause of the power failure. There are countless different designs and models on the market only among standard lift tables . All hydraulic cylinders must be fully retracted. If you can see oil leaking around the connections, it is sufficient to retighten the corresponding screw connection. If the electric motor of the hydraulic unit turns in the wrong direction, no oil is pumped from the tank into the cylinders. If this seat is dirty, the ball no longer seals properly. Depending on the extent of the damage, bearing bolts and other adjacent components may also have to be replaced. The power supply to the drive is interrupted when the emergency stop switch is pressed. If the noise originates in the area of the hydraulic unit, this indicates a defective pump or electric motor. If the lift table initially had enough hydraulic oil to lift the platform, the oil must have leaked somewhere. The next step is the on-site construction and installation of the equipment. Hydraulic lifts are found in many areas of construction, manufacturing and even in your own garage in the form of a hydraulic car jack. This is connected to the control system in such a way that the lowering and lifting movement of the platform is blocked when a programmed pressure is exceeded. This means that although you can hear the hydraulic motor being actuated and started, the lift table does not lift. Another frequent fault is that the platform of the lift table can no longer be lowered. Localising the origin of the noise is the most important means of troubleshooting this problem. If the hydraulic lines have been laid correctly, a leak directly on the hydraulic unit or on the cylinders (damaged seals) is most likely. You risk losing the manufacturer's warranty by making any changes or modifications. Remove the load from the lift table whenever possible. This oil is not available for use in the cylinders. As a rule, the power unit does not have to be activated to lower the platform of hydraulic lift tables. The customer of the rail-type elevator freight elevator stopped the failure because of self-adjusting the overflow valve. This prevents the hydraulic oil under pressure to flow from the cylinders via the pump back into the tank. Below is a list of the most common causes of faults. If the electric motor does not run, another reason could be that the motor windings have worn out and the motor may need to be replaced. Tighten the line fittings or replace them. If hydraulic oil leaks, replace the composite pad or wrap the raw material tape. A lack of oil can almost certainly be ruled out if the lift table has been subjected to a professional final inspection and shipped properly. For this reason, the lowering movement of the lift table is stopped. They are used to turn off the hydraulic power unit in the top position and to close the lowering valve in the bottom position. Lets assume a load is only lifted by the hydraulic oil in the cylinders.  Move the lift table against pressure, hold down the button for a short time and repeat the procedure until the air has escaped from the hydraulic circuit. This could damage the hose. At least one check valve is installed in the hydraulic system of the lift table. %PDF-1.6

%

Please note that this usually does not affect the control voltage of the lift table. The equipment has landed safely, this is the customer needs to verify whether the tonnage, size, parameters, accessories, etc. If the operating pressure exceeds the set pressure of the pressure relief valve, oil flows back into the tank. In other words, what was the reason for the fuse to blow or to have blown? Check whether hydraulic oil has leaked somewhere and fix the leak. You can obtain more detailed information by clicking on a possible cause of the fault. However, it cannot be ruled out that a fault in the control system may open the valves by mistake. The power unit may not be running on three phases, but only on two. The escaping hydraulic oil must be collected with a cloth. This fault is usually not easy to fix. As a result, the lift table stops in the wrong position. As soon as no more air pockets can be detected in the hydraulic oil, the hydraulic screw connection can be tightened again. The acceleration forces that occur cause the set pressure of the pressure relief valve to be exceeded, resulting in some of the oil flowing back into the tank. There may be leakage in the hydraulic system. Depending on the service life, the individual bearings of the lift table may have to be regreased or, in the case of non-greasable bearings, completely replaced. Forklift and crane loading and unloading must be smoothly transitioned. As a rule, you should leave this work to the lift table manufacturer. General safety instructions are listed at the end of this article. However, more important than rectifying the fault is the question of where the old hydraulic oil is. To rectify this fault, you must raise the lift platform again to open the pipe rupture safety valves. Always follow the instructions of the lift table manufacturer regardless of the kind of work being done on the lift table. Depending on where the noise comes from, the following causes of the fault are likely: Most lift tables are equipped with maintenance-free plain bearings. Work may only be carried out by personnel trained by the manufacturer or by qualified technicians. But it can also be an insulation fault and an associated short circuit. The emergency stop switch is often used to turn off the machine. The operating instructions supplied with the lift table will usually contain the relevant information. If the pressure in the hydraulic system is too high, part of the oil is pumped directly into the power unit tank to protect the lift table components against damage.Furthermore, the motor protection switch of the drive motor may have tripped. In lifting tables with a bleed screw, slightly opening the screw is sufficient to allow oil to escape from the pressurised cylinders. )z(7BOS~~oGz7OVG?_/Iu `on`G * DAjx If there is a problem, clean or replace the hydraulic valve in time. If there is little or no oil left in the hydraulic unit, the cylinders do not extend and the platform of the lift table does not lift. When the speed of the hydraulic lifting platform slows down, check whether the oil supply flow of the hydraulic pump is stable. Mobile Phone: +8618660129317 (Whatsapp/Viber/Wechat), After-Sales Service Hotline: +86 133 6106 4776, Address: No.14, Xinlonghai Industrial Park, Qudi Town, Jiyang District, Jinan, China, The Best Way of Hydraulic Goods Lift Trouble shooting, The Best Way of Hydraulic Goods Lift Troubleshooting, Failure adjustment of hydraulic goods lift, How to make sure your hydraulic goods lift under good condition, 14m Trailer Boom Lift for Our Fiji Client, How better to use warehouse goods lift correctly. Wir nutzen Cookies, um unsere Dienste zu erbringen und zu verbessern. A replacement is inevitable. Make sure not to overtighten screw connections on hoses. The lowering valve is another valve that could cause the described problem. Simply click on the link for a detailed explanation of the cause of the fault and a suggested solution. Bulldozers, fork lifts, airplanes and cranes all employ hydraulic lift systems. Therefore, please only hand-tighten the hoses. Very often the cause is simply that the lift table is overloaded. In the worst case, the valve must be replaced. To find the solution to your problem, simply select the appropriate heading in the following section. Lift tables usually have a surrounding safety edge to prevent objects or limbs from being trapped between the platform and the base frame of the lift table.If the safety edge is activated, the lift table can no longer be lowered any further and the platform can only be raised. Maintenance support struts must always be used and safety glasses etc. As with all faults, it is important to question why it has occurred. The above is the knowledge of freight elevator transportation and loading and unloading, I hope it will be useful to everyone. A pressure relief valve can only protect a lift table from overload during lifting. It connects the pressure line directly to the hydraulic tank.

Move the lift table against pressure, hold down the button for a short time and repeat the procedure until the air has escaped from the hydraulic circuit. This could damage the hose. At least one check valve is installed in the hydraulic system of the lift table. %PDF-1.6

%

Please note that this usually does not affect the control voltage of the lift table. The equipment has landed safely, this is the customer needs to verify whether the tonnage, size, parameters, accessories, etc. If the operating pressure exceeds the set pressure of the pressure relief valve, oil flows back into the tank. In other words, what was the reason for the fuse to blow or to have blown? Check whether hydraulic oil has leaked somewhere and fix the leak. You can obtain more detailed information by clicking on a possible cause of the fault. However, it cannot be ruled out that a fault in the control system may open the valves by mistake. The power unit may not be running on three phases, but only on two. The escaping hydraulic oil must be collected with a cloth. This fault is usually not easy to fix. As a result, the lift table stops in the wrong position. As soon as no more air pockets can be detected in the hydraulic oil, the hydraulic screw connection can be tightened again. The acceleration forces that occur cause the set pressure of the pressure relief valve to be exceeded, resulting in some of the oil flowing back into the tank. There may be leakage in the hydraulic system. Depending on the service life, the individual bearings of the lift table may have to be regreased or, in the case of non-greasable bearings, completely replaced. Forklift and crane loading and unloading must be smoothly transitioned. As a rule, you should leave this work to the lift table manufacturer. General safety instructions are listed at the end of this article. However, more important than rectifying the fault is the question of where the old hydraulic oil is. To rectify this fault, you must raise the lift platform again to open the pipe rupture safety valves. Always follow the instructions of the lift table manufacturer regardless of the kind of work being done on the lift table. Depending on where the noise comes from, the following causes of the fault are likely: Most lift tables are equipped with maintenance-free plain bearings. Work may only be carried out by personnel trained by the manufacturer or by qualified technicians. But it can also be an insulation fault and an associated short circuit. The emergency stop switch is often used to turn off the machine. The operating instructions supplied with the lift table will usually contain the relevant information. If the pressure in the hydraulic system is too high, part of the oil is pumped directly into the power unit tank to protect the lift table components against damage.Furthermore, the motor protection switch of the drive motor may have tripped. In lifting tables with a bleed screw, slightly opening the screw is sufficient to allow oil to escape from the pressurised cylinders. )z(7BOS~~oGz7OVG?_/Iu `on`G * DAjx If there is a problem, clean or replace the hydraulic valve in time. If there is little or no oil left in the hydraulic unit, the cylinders do not extend and the platform of the lift table does not lift. When the speed of the hydraulic lifting platform slows down, check whether the oil supply flow of the hydraulic pump is stable. Mobile Phone: +8618660129317 (Whatsapp/Viber/Wechat), After-Sales Service Hotline: +86 133 6106 4776, Address: No.14, Xinlonghai Industrial Park, Qudi Town, Jiyang District, Jinan, China, The Best Way of Hydraulic Goods Lift Trouble shooting, The Best Way of Hydraulic Goods Lift Troubleshooting, Failure adjustment of hydraulic goods lift, How to make sure your hydraulic goods lift under good condition, 14m Trailer Boom Lift for Our Fiji Client, How better to use warehouse goods lift correctly. Wir nutzen Cookies, um unsere Dienste zu erbringen und zu verbessern. A replacement is inevitable. Make sure not to overtighten screw connections on hoses. The lowering valve is another valve that could cause the described problem. Simply click on the link for a detailed explanation of the cause of the fault and a suggested solution. Bulldozers, fork lifts, airplanes and cranes all employ hydraulic lift systems. Therefore, please only hand-tighten the hoses. Very often the cause is simply that the lift table is overloaded. In the worst case, the valve must be replaced. To find the solution to your problem, simply select the appropriate heading in the following section. Lift tables usually have a surrounding safety edge to prevent objects or limbs from being trapped between the platform and the base frame of the lift table.If the safety edge is activated, the lift table can no longer be lowered any further and the platform can only be raised. Maintenance support struts must always be used and safety glasses etc. As with all faults, it is important to question why it has occurred. The above is the knowledge of freight elevator transportation and loading and unloading, I hope it will be useful to everyone. A pressure relief valve can only protect a lift table from overload during lifting. It connects the pressure line directly to the hydraulic tank.

- Waterproof Light Socket With Cord

- White Woven Ruched Detail Midi Skirt

- 1950 Ford Flatbed Truck For Sale

- Bamba's Peanut Butter Puffs

- Where Is Trending Custom Located

- Shape Books For Kindergarten

- Maxi Maternity Dresses For Baby Shower

- Spearfishing Playa Del Carmen

- Hotel Alphubel Zermatt

- Black And White Striped Shirt Long Sleeve Women's

- Eiffel Tower Viewing Deck Tickets

- Torrid Minnie Mouse Sweatshirt

- Left-handed Electric Guitar Body

- Valentino Size Chart Men's

- Louis Vuitton Sarah Wallet Blue

- Large Microwave Table

- Filson Original Briefcase