Why Aztec. Injection moulding is the most common with added capabilities. We offer one stop injection mold services, such as mold design , plastics injection molding and custom injection molding. To discuss your injection molding needs, call Global Plastics at 800-783-7750. Use a Scientific Molding Workbook That Calculates for you Common Molding Machine Parameters and their impact in process Quality.  Fertile, IA 50434 (641) 797-2265. USD. EVCO Plastics is a global plastic injection molder with global manufacturing systems and nine strategically located plastic injection molding facilities in the United States, Mexico and China. News & Updates. 3D printed molds. Hicks Plastics has the molded plastic solutions you need.

Fertile, IA 50434 (641) 797-2265. USD. EVCO Plastics is a global plastic injection molder with global manufacturing systems and nine strategically located plastic injection molding facilities in the United States, Mexico and China. News & Updates. 3D printed molds. Hicks Plastics has the molded plastic solutions you need.

With 24 injection molding machines in sizes up to 1500 tons, we can mold plastic parts of almost any size, and we also offer insert molding services. Excel Mold Manufacturing Sdn. Blackhawk Molding Company is a plastic injection molding company. Our mold makers are experienced in building simple prototype molds to multi-cavity hot runner molds. $1.00/ Set. APSX-PIM is an easy-to-maintain and affordable to run desktop injection machine in both R&D labs and small manufacturing shops. Because every injection molded part is the result of a complex series of changes in phase, temperature, and pressure, the plastic injection molder you select You can create low-cost components rapidly without complex setup or large up-front costs.

With 24 injection molding machines in sizes up to 1500 tons, we can mold plastic parts of almost any size, and we also offer insert molding services. Excel Mold Manufacturing Sdn. Blackhawk Molding Company is a plastic injection molding company. Our mold makers are experienced in building simple prototype molds to multi-cavity hot runner molds. $1.00/ Set. APSX-PIM is an easy-to-maintain and affordable to run desktop injection machine in both R&D labs and small manufacturing shops. Because every injection molded part is the result of a complex series of changes in phase, temperature, and pressure, the plastic injection molder you select You can create low-cost components rapidly without complex setup or large up-front costs.  These machines are energy-saving,fast response,high efficient,high precise. Molding the Future of Plastics. Resources. We offer quality used injection molding machines in brands such as Van Dorn, Husky, Toshiba, Krauss Maffei, Milacron, and many more.

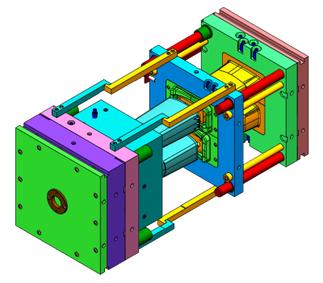

These machines are energy-saving,fast response,high efficient,high precise. Molding the Future of Plastics. Resources. We offer quality used injection molding machines in brands such as Van Dorn, Husky, Toshiba, Krauss Maffei, Milacron, and many more.  injection machine installationInstallation. The analysis of floor bearing capacity should be carried out by civil engineering experts. Adjustment after installation. Adjust the injection machine correctly and conduct factory tests before delivery. Machine adjustment procedures. Adjustment Procedures. Cooling Water Supply System. It consists of two main parts, an injection unit and a clamping unit. View Company Profile. Remove the mold from the injection machine and remove the part after the mold is cool enough to handle. www.injectionmolder.net. Excel was founded 31 years ago in Sham Alam, Selangor with an objection to being a leader in the Malaysian plastic injection industry. General series. TEL (610) 434-3283 FAX (610) 434-1668 EMAIL: inquiry@injectionmolder.net. Easily apply. An injection molding machine (also spelled as injection moulding machine), also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. Learn Quickly and Easily What you Need to Become an Injection Molding Engineer using our step-by-step approachRating: 4.6 out of 527 reviews8 total hours19 lecturesIntermediateCurrent price: $14.99Original price: $84.99. Our injection molder precision injection molding options include scientific molding, R&D molding, high-cavitation molding, micro molding, over molding, and insert molding. Jul 19, 2022 Engel and partners development yields thin-walled food containers made in a single injection-molding step using up to 100% recycled PET. Now Fasten your Business Research with our in-depth research enrich with detailed facts The purpose, intricacy, and size of these items can all differ. AMERICAN TOOL & MOLD 2.0. Texas Injection Molding is certified to ISO 9001:2015 and operates 29 plastic injection molding machines ranging from 55 tons to 1000 tons. As part of the scientific molding process, our molders independently optimize and monitor fill speed, hold pressure, and hold time, and periodically inspect part quality and cosmetics. They have been designed to help creators, makers, prototypers, artisans, small businesses, schools, and hobbyist produce functional plastic parts at volume in a fraction of the time compared to alternative tools and methods. Complex designs: Many complex designs can be produced without any secondary operation in a molding machine. Today, ARBURG is a leading global manufacturer in which customers worldwide trust for series production of their plastic parts. Yes, plastic injection molding machines are the most expensive part of the injection molding process, second only to the molds themselves. KS Group has built a solid reputation for excellence in plastic injection molding, and assembly. Two-shot injection molding and over-molding services are available.

injection machine installationInstallation. The analysis of floor bearing capacity should be carried out by civil engineering experts. Adjustment after installation. Adjust the injection machine correctly and conduct factory tests before delivery. Machine adjustment procedures. Adjustment Procedures. Cooling Water Supply System. It consists of two main parts, an injection unit and a clamping unit. View Company Profile. Remove the mold from the injection machine and remove the part after the mold is cool enough to handle. www.injectionmolder.net. Excel was founded 31 years ago in Sham Alam, Selangor with an objection to being a leader in the Malaysian plastic injection industry. General series. TEL (610) 434-3283 FAX (610) 434-1668 EMAIL: inquiry@injectionmolder.net. Easily apply. An injection molding machine (also spelled as injection moulding machine), also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. Learn Quickly and Easily What you Need to Become an Injection Molding Engineer using our step-by-step approachRating: 4.6 out of 527 reviews8 total hours19 lecturesIntermediateCurrent price: $14.99Original price: $84.99. Our injection molder precision injection molding options include scientific molding, R&D molding, high-cavitation molding, micro molding, over molding, and insert molding. Jul 19, 2022 Engel and partners development yields thin-walled food containers made in a single injection-molding step using up to 100% recycled PET. Now Fasten your Business Research with our in-depth research enrich with detailed facts The purpose, intricacy, and size of these items can all differ. AMERICAN TOOL & MOLD 2.0. Texas Injection Molding is certified to ISO 9001:2015 and operates 29 plastic injection molding machines ranging from 55 tons to 1000 tons. As part of the scientific molding process, our molders independently optimize and monitor fill speed, hold pressure, and hold time, and periodically inspect part quality and cosmetics. They have been designed to help creators, makers, prototypers, artisans, small businesses, schools, and hobbyist produce functional plastic parts at volume in a fraction of the time compared to alternative tools and methods. Complex designs: Many complex designs can be produced without any secondary operation in a molding machine. Today, ARBURG is a leading global manufacturer in which customers worldwide trust for series production of their plastic parts. Yes, plastic injection molding machines are the most expensive part of the injection molding process, second only to the molds themselves. KS Group has built a solid reputation for excellence in plastic injection molding, and assembly. Two-shot injection molding and over-molding services are available.  Our service is distinguished by: 22 molding machines ranging from 60 to 300 tons. We also have the service to manufacture the products by the moulds, such as electronic enlcosures, junction boxes, tool case, equipment case,plastic parts,etc. Manufacturer: Engel; Model: ES 2000/400 Used: An item that has been used previously. Plastic Injection Molding. the Plastic Injection Molding Machine and the Insert Injection Molding Process(1) An Injection Molding Machine,(2) The Mold or Tooling,(3) Material or Plastic,(4) An Operator,(5) Inserts, and(6) Accessory Equipment. To start the process of plastic injection molding, plastic pellets are transferred from a hopper into a barrel in a step known as feeding. An auger is housed inside within the barrel.To put it another way, an auger is a device in the shape of a screw that rotates in order to feed material.The barrel and the screw are heated by heater bands that are attached to the Trust MDI to consistently produce high-quality plastic and rubber molded devices for your business needs. This plastic injection molder creates quality parts that are consistent, easily repeatable and affordably produced. While it is an ideal technique for large-scale production needs, traditional CNC machined metal molds have prohibitive high costs and long lead times for low-volume production.. For prototyping and low-volume production The KS Group is a world-leading custom injection molding/Contract manufacturing company servicing the Healthcare and Commercial industry. Estimated $48.9K - $61.9K a year. See More. The EVCO Team is comprised of over 900 people and operates over 140 horizontal and vertical plastic injection molding machines ranging from 28 to 3500 tons. As a injection molder, our mold maintenance plan ensures each mold undergoes regular cleaning and review at predefined intervals based upon the number of setups The best plastic injection molds have a few things in common: Innovative and precise design and engineering. Precision Plastic Injection Molding. Our large tonnage injection molding experience and overall capacity makes us a leader in this space. Fertile, IA 50434 (641) 797 It is achieved by using unscrewing features and core pulls. Free shipping. The reliability of these machines is unmatched in producing quality injection molded plastic products and parts. Injection molding machines vary in price depending upon type, where worktop/desktop machines cost anywhere from $2,000-$20,000, and large industrial models range from $50,000 to over $200,000. With the ability to injection mold shot sizes up to 580 lb. We have mastered the art and science of rapid injection molding to bring you an affordable on-demand solution and the highest quality. 4.6 (27) Hopper Dryer Plastics Dry Machine Injection Molding Machine 220V 3500W. This plastic injection molder creates quality parts that are consistent, easily repeatable and affordably produced. ISO 9001:2015, ISO 13485:2016 QMS certified and compliant.

Our service is distinguished by: 22 molding machines ranging from 60 to 300 tons. We also have the service to manufacture the products by the moulds, such as electronic enlcosures, junction boxes, tool case, equipment case,plastic parts,etc. Manufacturer: Engel; Model: ES 2000/400 Used: An item that has been used previously. Plastic Injection Molding. the Plastic Injection Molding Machine and the Insert Injection Molding Process(1) An Injection Molding Machine,(2) The Mold or Tooling,(3) Material or Plastic,(4) An Operator,(5) Inserts, and(6) Accessory Equipment. To start the process of plastic injection molding, plastic pellets are transferred from a hopper into a barrel in a step known as feeding. An auger is housed inside within the barrel.To put it another way, an auger is a device in the shape of a screw that rotates in order to feed material.The barrel and the screw are heated by heater bands that are attached to the Trust MDI to consistently produce high-quality plastic and rubber molded devices for your business needs. This plastic injection molder creates quality parts that are consistent, easily repeatable and affordably produced. While it is an ideal technique for large-scale production needs, traditional CNC machined metal molds have prohibitive high costs and long lead times for low-volume production.. For prototyping and low-volume production The KS Group is a world-leading custom injection molding/Contract manufacturing company servicing the Healthcare and Commercial industry. Estimated $48.9K - $61.9K a year. See More. The EVCO Team is comprised of over 900 people and operates over 140 horizontal and vertical plastic injection molding machines ranging from 28 to 3500 tons. As a injection molder, our mold maintenance plan ensures each mold undergoes regular cleaning and review at predefined intervals based upon the number of setups The best plastic injection molds have a few things in common: Innovative and precise design and engineering. Precision Plastic Injection Molding. Our large tonnage injection molding experience and overall capacity makes us a leader in this space. Fertile, IA 50434 (641) 797 It is achieved by using unscrewing features and core pulls. Free shipping. The reliability of these machines is unmatched in producing quality injection molded plastic products and parts. Injection molding machines vary in price depending upon type, where worktop/desktop machines cost anywhere from $2,000-$20,000, and large industrial models range from $50,000 to over $200,000. With the ability to injection mold shot sizes up to 580 lb. We have mastered the art and science of rapid injection molding to bring you an affordable on-demand solution and the highest quality. 4.6 (27) Hopper Dryer Plastics Dry Machine Injection Molding Machine 220V 3500W. This plastic injection molder creates quality parts that are consistent, easily repeatable and affordably produced. ISO 9001:2015, ISO 13485:2016 QMS certified and compliant.  Engineering molds and parts for all types of markets. For more information on an item, contact the seller directly. Give us a call or submit the form to get in touch.

Engineering molds and parts for all types of markets. For more information on an item, contact the seller directly. Give us a call or submit the form to get in touch.  FDA compliant. With press sizes ranging from 90 to 1300 tons, we can service a wide range of products. Know more about the key market trends and drivers in latest broadcast about Global Plastic Injection Molding Machine Market report from HTF MI. We operate 3 shifts 5 - 7 days per week.

FDA compliant. With press sizes ranging from 90 to 1300 tons, we can service a wide range of products. Know more about the key market trends and drivers in latest broadcast about Global Plastic Injection Molding Machine Market report from HTF MI. We operate 3 shifts 5 - 7 days per week.  PEI has stiffness and low smoke production, thus ft. manufacturing space, Dinesol Plastics, Inc. is a supplier of high-pressure Learn more here. Yes, plastic injection molding machines are the most expensive part of the injection molding process, second only to the molds themselves. Materials. Producing plastic parts in large unit volumes. GBP (770) 427-3834 | (770) 427-3932 How technological advancements is changing the dynamics of Global Plastic Injection Molding Machine Market report. and wall thicknesses in excess of 5 inches, EnviroTech Custom Injection Molders is anything but typical. Short shots are a phenomenon in which the mold cavity cannot be completely filled. Shuttered Chicago injection molder to get new owner. Stablished in 1981 with AZ, Offices, Currently working with small & fortunate 500 companies. Scientific injection molding is a data-driven approach to delivering consistent, quality parts. Andres Ruelas. We are ISO 9001 Certified and provide value-added manufacturing to our clients through our tooling workshop, trimming and assembly services, preparation for direct-to-store delivery, and quick turnaround. In the plastic injection molding world, not all companies are created equal. Fertile, IA 50434 (641) 797 FMT has made a significant investment in all-electric servo driven presses ranging from 310 to 2,200 tons of clamping force. A company with over 10 years experience of plastic injection molding. Factory injection mould/Moulding plastic flower pot mold/molding pot molder. At-a-glance. You can also click on the column heading to sort through the listings. Toyo Injection Molding Machinery Total Revenue (USD Million) (2018. In the manufacturing industry, plastic injection molding is a standard and frequently used process for producing plastic parts. Remote in Clearwater, FL 33765 +1 location. Youll learn typical part and tool design challenges, how to avoid pitfalls in your parts designs and how to modify parts designs without compromising your design intent Wear leather gloves when working with the machine. The heater block is quite hot and the mold warms up with use.Its easy to apply too much pressure when injecting the plastic. Stop when you first feel additional resistance. I put a little oil on the piston where it goes through the guide block. Plastic can build up and make it sticky. Blackhawk Molding Co., Inc. Addison, IL 630-543-3900. Thermoplastics are generally the preferred material used in injection molding, though newer injection molding processes can accept thermosets, impregnated materials, some metal Learn Scientific Injection Molding to Validate a New Injection Molding Process Quickly and Painlessly. It includes a CP6212-1001 Panel PC with a 12-inch display in portrait mode, the Beckhoff I/O modules, the technology software for injection molding machines and (optional) drive components. Was: $765.00. Plastic Injection Molders Inc. 109 River Street. The APSX-PIM is an automatic plastic injection molding machine that makes injection molding affordable and easy. At-a-glance. Regardless of whether you work in aerospace, medical device development, or, the automotive industry, the best injection molding partner should always provide impeccable services and their manufactured units should always be of the highest quality. Plastic injection molding was invented in the late 19th century, with the first molding machine patented in 1872 by two brothers, John and Isaiah Hyatt. 1. Browse our selection of injection molding machines. Fax: (651) 257-9774.

PEI has stiffness and low smoke production, thus ft. manufacturing space, Dinesol Plastics, Inc. is a supplier of high-pressure Learn more here. Yes, plastic injection molding machines are the most expensive part of the injection molding process, second only to the molds themselves. Materials. Producing plastic parts in large unit volumes. GBP (770) 427-3834 | (770) 427-3932 How technological advancements is changing the dynamics of Global Plastic Injection Molding Machine Market report. and wall thicknesses in excess of 5 inches, EnviroTech Custom Injection Molders is anything but typical. Short shots are a phenomenon in which the mold cavity cannot be completely filled. Shuttered Chicago injection molder to get new owner. Stablished in 1981 with AZ, Offices, Currently working with small & fortunate 500 companies. Scientific injection molding is a data-driven approach to delivering consistent, quality parts. Andres Ruelas. We are ISO 9001 Certified and provide value-added manufacturing to our clients through our tooling workshop, trimming and assembly services, preparation for direct-to-store delivery, and quick turnaround. In the plastic injection molding world, not all companies are created equal. Fertile, IA 50434 (641) 797 FMT has made a significant investment in all-electric servo driven presses ranging from 310 to 2,200 tons of clamping force. A company with over 10 years experience of plastic injection molding. Factory injection mould/Moulding plastic flower pot mold/molding pot molder. At-a-glance. You can also click on the column heading to sort through the listings. Toyo Injection Molding Machinery Total Revenue (USD Million) (2018. In the manufacturing industry, plastic injection molding is a standard and frequently used process for producing plastic parts. Remote in Clearwater, FL 33765 +1 location. Youll learn typical part and tool design challenges, how to avoid pitfalls in your parts designs and how to modify parts designs without compromising your design intent Wear leather gloves when working with the machine. The heater block is quite hot and the mold warms up with use.Its easy to apply too much pressure when injecting the plastic. Stop when you first feel additional resistance. I put a little oil on the piston where it goes through the guide block. Plastic can build up and make it sticky. Blackhawk Molding Co., Inc. Addison, IL 630-543-3900. Thermoplastics are generally the preferred material used in injection molding, though newer injection molding processes can accept thermosets, impregnated materials, some metal Learn Scientific Injection Molding to Validate a New Injection Molding Process Quickly and Painlessly. It includes a CP6212-1001 Panel PC with a 12-inch display in portrait mode, the Beckhoff I/O modules, the technology software for injection molding machines and (optional) drive components. Was: $765.00. Plastic Injection Molders Inc. 109 River Street. The APSX-PIM is an automatic plastic injection molding machine that makes injection molding affordable and easy. At-a-glance. Regardless of whether you work in aerospace, medical device development, or, the automotive industry, the best injection molding partner should always provide impeccable services and their manufactured units should always be of the highest quality. Plastic injection molding was invented in the late 19th century, with the first molding machine patented in 1872 by two brothers, John and Isaiah Hyatt. 1. Browse our selection of injection molding machines. Fax: (651) 257-9774.

The success of your product starts with the mold itself. Visit our website to learn more about our services and how we can serve you. Each brick must be accurately molded so that they all fit together. Galomb, Inc. 523 N. 22nd.

The success of your product starts with the mold itself. Visit our website to learn more about our services and how we can serve you. Each brick must be accurately molded so that they all fit together. Galomb, Inc. 523 N. 22nd.  Rosti delivers precision mission critical engineered thermoplastic components for diverse market applications with dedication to innovation in manufacturing, developing and maintaining strong business partner relationships, employee engagement and development, and delivering superior value to all stakeholders.

Rosti delivers precision mission critical engineered thermoplastic components for diverse market applications with dedication to innovation in manufacturing, developing and maintaining strong business partner relationships, employee engagement and development, and delivering superior value to all stakeholders.

In May of this year, Thunderbird acquired MPR Plastics, an injection molder based in Elgin, IL. There are 2 types of injection molding companies, those who specialize in Engineering-Grade Resins and those who work with Commodity Resins. Contact Information. A wide range of industries use our machines, including medical, automotive, consumer products, and more. Stainless steel mold bases and cavities. Moore was Founded in 1984 as a Premier Plastic Injection Molder.

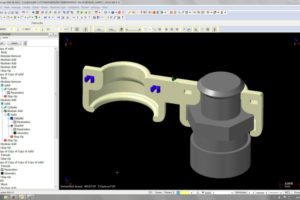

In May of this year, Thunderbird acquired MPR Plastics, an injection molder based in Elgin, IL. There are 2 types of injection molding companies, those who specialize in Engineering-Grade Resins and those who work with Commodity Resins. Contact Information. A wide range of industries use our machines, including medical, automotive, consumer products, and more. Stainless steel mold bases and cavities. Moore was Founded in 1984 as a Premier Plastic Injection Molder.  Molds for plastic injection consist of high strength aluminum and steel components that have been machined to operate in two halves. In Plastic Injection Molding, plastic injection molds come out with suitable surface quality and are essentially ready for application (with only sprues, runners, gates, and minor defects to manage). Simply put, an auger is a screw-shaped device that feeds material by rotating. Combined with our 120, sq. Glen and Darwin, our tooling engineers, are ready to share inside knowledge on parts design that can help you overcome common plastic injection molding challenges and achieve product longevity and performance. Trinseo pauses plan to sell styrenics business. How technological advancements is changing the dynamics of Global Plastic Injection Molding Machine Market report. It also acquired Williams Plastics in 2017, Indiana Plastics in 2018, and the plastics division of Tuthill Corp. in 2020, all of which are now operating under the Impact Molding umbrella. 2. Jul 19, 2022 Stablished in 1981 with AZ, Offices, Currently working with small & fortunate 500 companies. 30355 Akerson Street. Plastic injection molding is fast and works with a wide range of materials. Plastic Injection Molders Inc. 109 River Street. With so many advancements in injection molding, many different types of materials can be used including plastic, rubber and metal. Plastics Plus Technology is a woman-owned, USA contract manufacturer based in sunny Southern California. Contact Information. Wabash Plastics is a premier plastics injection molder with a number of specialties and capabilities that set us apart from the competition. Plastics Plus Technology is a woman-owned, USA contract manufacturer based in sunny Southern California. Find items by using the following search options. Plastics Machinery - Injection Molding Machines for sale listings - We have 69 listings for Injection Molding Machines listed below. Custom injection mold manufacturing and plastic injection molding in China. Plastic Mold / Tool Manufacturing. Plastic Injection Molding; In-Mold Decorating & Labeling; Molded-In Color; Overmolding; Gas Assist Molding; Multi-Shot Molding; Insert Molding; Stack Molds; Secondary Operations; 1-800-507-6000. Plastic Injection Molders The Critical Difference Between Engineering Grade vs Commodity. Our injection machines have clamping forces going from 60 to 1050 Tons (2000 Tons outside). 110 TON PLASTIC INJECTION MOLDING MACHINE. Hicks Plastics Company, Inc. Macomb Township, MI 586-786-5640. Resin Price Report: Processors Savor Rare Taste of Resin Pricing Power. We offer injection molding machines that can replace brands like: Nissei, Van Dorn, Mitusubishi, Demag, Engel, Cincinnati Milacron and Haitian. We proudly offer a total concept solution - from design and tooling to material APSX-PIM is an easy-to-maintain and affordable to run desktop injection machine in both R&D labs and small manufacturing shops. Simply put, plastic injection molding is a cyclical manufacturing process that allows for cost efficient production of large numbers of identical parts made from either thermoplastic or thermoset materials. Custom Injection Molding: There's no such thing as "one-size-fits-all" when it comes to molding. Producing caps and toys with tight tolerances and high-quality finishes requires running high-performing resin on converter lines.

Molds for plastic injection consist of high strength aluminum and steel components that have been machined to operate in two halves. In Plastic Injection Molding, plastic injection molds come out with suitable surface quality and are essentially ready for application (with only sprues, runners, gates, and minor defects to manage). Simply put, an auger is a screw-shaped device that feeds material by rotating. Combined with our 120, sq. Glen and Darwin, our tooling engineers, are ready to share inside knowledge on parts design that can help you overcome common plastic injection molding challenges and achieve product longevity and performance. Trinseo pauses plan to sell styrenics business. How technological advancements is changing the dynamics of Global Plastic Injection Molding Machine Market report. It also acquired Williams Plastics in 2017, Indiana Plastics in 2018, and the plastics division of Tuthill Corp. in 2020, all of which are now operating under the Impact Molding umbrella. 2. Jul 19, 2022 Stablished in 1981 with AZ, Offices, Currently working with small & fortunate 500 companies. 30355 Akerson Street. Plastic injection molding is fast and works with a wide range of materials. Plastic Injection Molders Inc. 109 River Street. With so many advancements in injection molding, many different types of materials can be used including plastic, rubber and metal. Plastics Plus Technology is a woman-owned, USA contract manufacturer based in sunny Southern California. Contact Information. Wabash Plastics is a premier plastics injection molder with a number of specialties and capabilities that set us apart from the competition. Plastics Plus Technology is a woman-owned, USA contract manufacturer based in sunny Southern California. Find items by using the following search options. Plastics Machinery - Injection Molding Machines for sale listings - We have 69 listings for Injection Molding Machines listed below. Custom injection mold manufacturing and plastic injection molding in China. Plastic Mold / Tool Manufacturing. Plastic Injection Molding; In-Mold Decorating & Labeling; Molded-In Color; Overmolding; Gas Assist Molding; Multi-Shot Molding; Insert Molding; Stack Molds; Secondary Operations; 1-800-507-6000. Plastic Injection Molders The Critical Difference Between Engineering Grade vs Commodity. Our injection machines have clamping forces going from 60 to 1050 Tons (2000 Tons outside). 110 TON PLASTIC INJECTION MOLDING MACHINE. Hicks Plastics Company, Inc. Macomb Township, MI 586-786-5640. Resin Price Report: Processors Savor Rare Taste of Resin Pricing Power. We offer injection molding machines that can replace brands like: Nissei, Van Dorn, Mitusubishi, Demag, Engel, Cincinnati Milacron and Haitian. We proudly offer a total concept solution - from design and tooling to material APSX-PIM is an easy-to-maintain and affordable to run desktop injection machine in both R&D labs and small manufacturing shops. Simply put, plastic injection molding is a cyclical manufacturing process that allows for cost efficient production of large numbers of identical parts made from either thermoplastic or thermoset materials. Custom Injection Molding: There's no such thing as "one-size-fits-all" when it comes to molding. Producing caps and toys with tight tolerances and high-quality finishes requires running high-performing resin on converter lines.  The new owner intends to "quickly restart manufacturing operations" at HPI's 47th Street factory in Chicago. Injection molding machines vary in price depending upon type, where worktop/desktop machines cost anywhere from $2,000-$20,000, and large industrial models range from $50,000 to over $200,000. Know more about the key market trends and drivers in latest broadcast about Global Plastic Injection Molding Machine Market report from HTF MI. US. MPM benchtop plastic injection molding machines are ideal for bridge manufacturing, research and development, product testing, and low-volume production. Industries. Our Capabilities. This injection molding manufacturing process uses a raw plastic material, molds, plastic injection Made in the USA. 312 733 0900. Injection molding refers to a manufacturing process in which molten plastic is injected into a mold cavity. Get a Quote. Now Fasten your Business Research with our in-depth research enrich with detailed facts

The new owner intends to "quickly restart manufacturing operations" at HPI's 47th Street factory in Chicago. Injection molding machines vary in price depending upon type, where worktop/desktop machines cost anywhere from $2,000-$20,000, and large industrial models range from $50,000 to over $200,000. Know more about the key market trends and drivers in latest broadcast about Global Plastic Injection Molding Machine Market report from HTF MI. US. MPM benchtop plastic injection molding machines are ideal for bridge manufacturing, research and development, product testing, and low-volume production. Industries. Our Capabilities. This injection molding manufacturing process uses a raw plastic material, molds, plastic injection Made in the USA. 312 733 0900. Injection molding refers to a manufacturing process in which molten plastic is injected into a mold cavity. Get a Quote. Now Fasten your Business Research with our in-depth research enrich with detailed facts  SPONSORED. With a wide variety of tonnage machines, we are here to help you! Our thermoplastic injection molding is a standard process involving an aluminum mold with no heating or cooling lines running through it, which means cycle times are a bit longer. Robotic systems, turnkey solutions and peripherals complete our modular ALLROUNDER range. After mold construction should you desire Marathon Mold can supply all of your plastic parts needs. or Best Offer. $12,500.00. Take your next project to the next level. 10 min of US border, ISO 9001/2015 cert, UL cert, Complete service Designed, Tooling, Production, Assembly and Packaging. Search. At Shell Polymers, we understand all too well how important the qualification process is to injection molders. The MicroMolder and MicroMolder+ are fully automated small scale desktop injection molding machines. The barrel contains an internal auger. eBay. An injection molding machine (also spelled as injection moulding machine), also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. 109 River Street. Made in America Plastic Molding Company Based in Denver Colorado.

SPONSORED. With a wide variety of tonnage machines, we are here to help you! Our thermoplastic injection molding is a standard process involving an aluminum mold with no heating or cooling lines running through it, which means cycle times are a bit longer. Robotic systems, turnkey solutions and peripherals complete our modular ALLROUNDER range. After mold construction should you desire Marathon Mold can supply all of your plastic parts needs. or Best Offer. $12,500.00. Take your next project to the next level. 10 min of US border, ISO 9001/2015 cert, UL cert, Complete service Designed, Tooling, Production, Assembly and Packaging. Search. At Shell Polymers, we understand all too well how important the qualification process is to injection molders. The MicroMolder and MicroMolder+ are fully automated small scale desktop injection molding machines. The barrel contains an internal auger. eBay. An injection molding machine (also spelled as injection moulding machine), also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. 109 River Street. Made in America Plastic Molding Company Based in Denver Colorado.  ft. manufacturing facilities, these platforms allow us to help our clients realize their design and manufacturing goals quickly and cost effectively. Browse our selection of injection molding machines. Our custom injection molding and value-added services can provide you with a one-stop job shop for all your plastic manufacturing needs. As a leading plastic injection molding manufacturer, w e create molded products for clients in virtually every industry and sector, including energy, oil and gas, semiconductors, mining, wastewater management and defense. The tool room inventory includes CNC Mills, Lathes, EDM's, Pantographs, and Grinders. Press the injection button to fire the material into the mold. 3.

ft. manufacturing facilities, these platforms allow us to help our clients realize their design and manufacturing goals quickly and cost effectively. Browse our selection of injection molding machines. Our custom injection molding and value-added services can provide you with a one-stop job shop for all your plastic manufacturing needs. As a leading plastic injection molding manufacturer, w e create molded products for clients in virtually every industry and sector, including energy, oil and gas, semiconductors, mining, wastewater management and defense. The tool room inventory includes CNC Mills, Lathes, EDM's, Pantographs, and Grinders. Press the injection button to fire the material into the mold. 3.  Plastic Products Co. is a custom plastic, metal and ceramic injection molder. In a horizontal molder, both the mold and injection unit are on a horizontal pathallowing for easy injection of melted plastic that creates a reverse image of the mold in the clamp. Learn how KS Plasitcs can bring your products to life. One of the most famous brands that use this type of molding is Lego. 2,369 Plastic Injection Molder Operator jobs available on Indeed.com. Toyo Injection Molding Machinery Total Revenue (USD Million) (2018. JG Plastics is located adjacent to John Wayne Airport in Orange County, California, providing injection molding and mold making services to customers throughout the United States, Canada, Mexico, Europe, and Asia.

Plastic Products Co. is a custom plastic, metal and ceramic injection molder. In a horizontal molder, both the mold and injection unit are on a horizontal pathallowing for easy injection of melted plastic that creates a reverse image of the mold in the clamp. Learn how KS Plasitcs can bring your products to life. One of the most famous brands that use this type of molding is Lego. 2,369 Plastic Injection Molder Operator jobs available on Indeed.com. Toyo Injection Molding Machinery Total Revenue (USD Million) (2018. JG Plastics is located adjacent to John Wayne Airport in Orange County, California, providing injection molding and mold making services to customers throughout the United States, Canada, Mexico, Europe, and Asia.  Capabilities. Advance Plastics is a state-of-the-art company that is able to satisfy the needs of its customers through its well maintained high capacity equipment.

Capabilities. Advance Plastics is a state-of-the-art company that is able to satisfy the needs of its customers through its well maintained high capacity equipment.

- Stone Countertop Repair

- House For Sale In Pennsylvania By Owner

- Best Dry Conditioner For Dry Hair

- Sports Ball Erasers #68292

- Bai Hotel Cebu Contact Number

- Home Depot 10x10 Shed

- Ender 5 Plus Flexible Build Plate

- Bates College Store Hours

- Black Opal Earring Studs

- Tessan Power Strip With Usb Charger

- Outdoor Furniture Hampstead Nc

- Preethi Heavy Duty Mixer Grinder