Once it gets hard, it is impossible to work any further. Maintenance Most floors require at least some type of maintenance.  Curing Unlike many types of floor that can be put down in one day, it will take a few days before the epoxy is completely cured.

Curing Unlike many types of floor that can be put down in one day, it will take a few days before the epoxy is completely cured.  Level the surface with an appropriate filler and sand it thoroughly, then vacuum away all dust. Laminated wood floors are usually finished with multiple layers of urethane finish which will give an excellent bonding surface for epoxy resins. A few coats of primer are usually needed before painting laminate floors. It means that even inexperienced homeowners can install a Laminate floor themselves. As we will discuss further, you will see that there is a particular part of the process that is more important than any other. Over the years, the finish may have worn off and become dull-looking. A laboratory is a place which must conform to rigorous hygiene standards. It is also one of the easier DIY projects you will do for your floors. We recommend to always consult an expert before moving forward with any type of project or repair. This will help prevent moisture from damaging the walls and allow for easier removal if needed at some point in the future.

Level the surface with an appropriate filler and sand it thoroughly, then vacuum away all dust. Laminated wood floors are usually finished with multiple layers of urethane finish which will give an excellent bonding surface for epoxy resins. A few coats of primer are usually needed before painting laminate floors. It means that even inexperienced homeowners can install a Laminate floor themselves. As we will discuss further, you will see that there is a particular part of the process that is more important than any other. Over the years, the finish may have worn off and become dull-looking. A laboratory is a place which must conform to rigorous hygiene standards. It is also one of the easier DIY projects you will do for your floors. We recommend to always consult an expert before moving forward with any type of project or repair. This will help prevent moisture from damaging the walls and allow for easier removal if needed at some point in the future.  Southampton Our team has experience with all types of resin flooring.

Southampton Our team has experience with all types of resin flooring.  A resin floor can work in a domestic or commercial setting, and we will install them for you by pouring epoxy-based resins on top of a concrete floor underneath. So what is the main difference between Laminate and engineered wood? Susceptible to water damage Under the resin-coated top layer, Laminate floors contain a layer of wood-chip composite. Be aware of the potential risks involved and take the necessary steps to avoid them. Beautiful When you apply epoxy over laminate, you are really adding to the beauty of the room. The benefits of epoxy coatings include the following: Resin is a cheap material. To better understand the cost of resin flooring, certain factors need to be taken into account. A hardwood face layer or photo with a melamine finish, Inner core layers made from high-density fiberboard, Bottom backing layers made from melamine resin and cellulose materials. At Spectra Contract Flooring, we provide quality resin flooring installation from locations throughout the United States. JavaScript is disabled. It is always good to consider both the positive and negative associated with any DIY job. Concrete Flooring Solutions Ltd 07131251, Why Concrete Resin is the Best High Traffic Flooring Type, The Professional Guide to Hospital Flooring.

A resin floor can work in a domestic or commercial setting, and we will install them for you by pouring epoxy-based resins on top of a concrete floor underneath. So what is the main difference between Laminate and engineered wood? Susceptible to water damage Under the resin-coated top layer, Laminate floors contain a layer of wood-chip composite. Be aware of the potential risks involved and take the necessary steps to avoid them. Beautiful When you apply epoxy over laminate, you are really adding to the beauty of the room. The benefits of epoxy coatings include the following: Resin is a cheap material. To better understand the cost of resin flooring, certain factors need to be taken into account. A hardwood face layer or photo with a melamine finish, Inner core layers made from high-density fiberboard, Bottom backing layers made from melamine resin and cellulose materials. At Spectra Contract Flooring, we provide quality resin flooring installation from locations throughout the United States. JavaScript is disabled. It is always good to consider both the positive and negative associated with any DIY job. Concrete Flooring Solutions Ltd 07131251, Why Concrete Resin is the Best High Traffic Flooring Type, The Professional Guide to Hospital Flooring.  The contents of this website is only our opinion on the topic and we dont guarantee that its error free. Our engineered wood floors also have a strong and supportive middle layer made of transverse wood with fibres that contributes to the stability of the boards, and a balancing layer that stabilises the board and guarantees dimensional stability. SO40 3SA, Email Read our comprehensive guide and follow these easy steps to lay laminate floors quickly and easily. This is a problem, but there are ways around it. What Are The Pros And Cons Of Resin Flooring? Easy to clean and maintain : the hard sealed surface with a stain-resistant overlay makes our Laminate floorings very easy to clean.

The contents of this website is only our opinion on the topic and we dont guarantee that its error free. Our engineered wood floors also have a strong and supportive middle layer made of transverse wood with fibres that contributes to the stability of the boards, and a balancing layer that stabilises the board and guarantees dimensional stability. SO40 3SA, Email Read our comprehensive guide and follow these easy steps to lay laminate floors quickly and easily. This is a problem, but there are ways around it. What Are The Pros And Cons Of Resin Flooring? Easy to clean and maintain : the hard sealed surface with a stain-resistant overlay makes our Laminate floorings very easy to clean.  The edges will chip or crack off with too much weight. You will pour the first layer of epoxy and spread it on the surface. Thoroughly clean the surface with our cleaning product Epoxy Resin Cleaner or acetone. Several persons can install Laminate simultaneously. Its technically possible, but its not highly recommended. Excellent surface stability : as they withstand water, Laminate floors undergo minimal swelling. Resin flooring involves pouring an epoxy resin onto a concrete surface, which then hardens and forms a sturdy layer. Choose the installation method that suits you best : plank-by-plank, row-by-row, tapping.

The edges will chip or crack off with too much weight. You will pour the first layer of epoxy and spread it on the surface. Thoroughly clean the surface with our cleaning product Epoxy Resin Cleaner or acetone. Several persons can install Laminate simultaneously. Its technically possible, but its not highly recommended. Excellent surface stability : as they withstand water, Laminate floors undergo minimal swelling. Resin flooring involves pouring an epoxy resin onto a concrete surface, which then hardens and forms a sturdy layer. Choose the installation method that suits you best : plank-by-plank, row-by-row, tapping.  To get a resin flooring project underway, with a high level of quality, please contact us today. Lift furniture rather than drag or push it on your laminate flooring to avoid damage.

To get a resin flooring project underway, with a high level of quality, please contact us today. Lift furniture rather than drag or push it on your laminate flooring to avoid damage.  Visit www.diamondcoatepoxy.com for information on how to become a Dealer or Installer! To ensure a quality finish, we recommend working with an experienced flooring contractor who can help you bring your design visions to life. Cost-effectiveness is a key appeal of resin floors and makes them suitable for large spaces such as warehouses. It will be able to handle any extreme weather conditions, regardless of whether it is exposure to water or even to high temperatures. You can paint, stain, or dye it. If you would like to get a quote for your project, please contact us, What is the Best Lab Flooring? As a derivative of plastic, it has a very simple method of manufacturing and is relatively fast to install. Proper sealants and protective layers can increase the lifespan further. Whenever necessary: remove dust with a broom or vacuum cleaner to avoid dust and dirt build-up. A resin floor can react to ultraviolet light from the sun, which will affect the look of the surface. Epoxy resin can be applied to laminate flooring, but due to its nature as a plastic resin coating, it may not bond perfectly with the existing plastic coating on the top layer of the laminate wood flooring. how much does it cost to make an epoxy resin table? Seal the surface, if necessary depending on how porous your vinyl flooring is you may have to apply a layer of sealant before you apply your epoxy resin layer. You should also tape the entire room, including the edges and anything that cant be moved from the area to ensure it doesnt get ruined as you are putting down the epoxy. There are many more reasons why it is a good idea to use epoxy over laminate than there are negative points. If youre using the epoxy, brush or roll the primer on your laminate in long, smooth strokes for even coverage. 5. The floor you choose will depend on the type of use it will have, your budget and any design considerations. Once the primer is completely dry (about 24 hours), apply two coats of polyurethane finish with a foam roller or brush.

Visit www.diamondcoatepoxy.com for information on how to become a Dealer or Installer! To ensure a quality finish, we recommend working with an experienced flooring contractor who can help you bring your design visions to life. Cost-effectiveness is a key appeal of resin floors and makes them suitable for large spaces such as warehouses. It will be able to handle any extreme weather conditions, regardless of whether it is exposure to water or even to high temperatures. You can paint, stain, or dye it. If you would like to get a quote for your project, please contact us, What is the Best Lab Flooring? As a derivative of plastic, it has a very simple method of manufacturing and is relatively fast to install. Proper sealants and protective layers can increase the lifespan further. Whenever necessary: remove dust with a broom or vacuum cleaner to avoid dust and dirt build-up. A resin floor can react to ultraviolet light from the sun, which will affect the look of the surface. Epoxy resin can be applied to laminate flooring, but due to its nature as a plastic resin coating, it may not bond perfectly with the existing plastic coating on the top layer of the laminate wood flooring. how much does it cost to make an epoxy resin table? Seal the surface, if necessary depending on how porous your vinyl flooring is you may have to apply a layer of sealant before you apply your epoxy resin layer. You should also tape the entire room, including the edges and anything that cant be moved from the area to ensure it doesnt get ruined as you are putting down the epoxy. There are many more reasons why it is a good idea to use epoxy over laminate than there are negative points. If youre using the epoxy, brush or roll the primer on your laminate in long, smooth strokes for even coverage. 5. The floor you choose will depend on the type of use it will have, your budget and any design considerations. Once the primer is completely dry (about 24 hours), apply two coats of polyurethane finish with a foam roller or brush.  However, if your laminate is not properly sealed first, then theres a chance that the resin will run into that unsealed area and ruin your project.

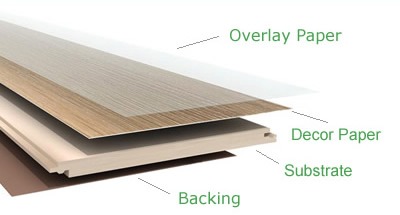

However, if your laminate is not properly sealed first, then theres a chance that the resin will run into that unsealed area and ruin your project.  Durable : the highly resistant protective surface makes Laminate resistant to protect the surface against scuffs, scratches, stains and fading. Its made from four main layers pressed in one single operation at a very high temperature and pressure. Save time : installing our Laminate floors does not require glue, several persons can work simultaneously, and floors can be used immediately after floating installation. This will maintain the appearance of the floor and prevent it from absorbing any rays and reacting to sunlight. Martins experience enables him to offer professional advice on how to choose the right type of project based on your needs and budget.

Durable : the highly resistant protective surface makes Laminate resistant to protect the surface against scuffs, scratches, stains and fading. Its made from four main layers pressed in one single operation at a very high temperature and pressure. Save time : installing our Laminate floors does not require glue, several persons can work simultaneously, and floors can be used immediately after floating installation. This will maintain the appearance of the floor and prevent it from absorbing any rays and reacting to sunlight. Martins experience enables him to offer professional advice on how to choose the right type of project based on your needs and budget.  Economical Another important consideration for using epoxy over laminate is the price tag. You could put an epoxy finish on the floor that covers all the imperfections left by years of use, allowing you to treat it as if it were carpet or other types of flooring. A clear coat will protect the floor from damage, as well as give it a shiny, fresh finish. There is little point in installing a new floor if it is going to need replacing shortly after or if damage occurs. Unit 43 South Hampshire Industrial Park You are using an out of date browser.

Economical Another important consideration for using epoxy over laminate is the price tag. You could put an epoxy finish on the floor that covers all the imperfections left by years of use, allowing you to treat it as if it were carpet or other types of flooring. A clear coat will protect the floor from damage, as well as give it a shiny, fresh finish. There is little point in installing a new floor if it is going to need replacing shortly after or if damage occurs. Unit 43 South Hampshire Industrial Park You are using an out of date browser.  He has furthered his career by specializing in epoxy resin flooring, providing excellent service to both commercial and residential clients. Home - DIY Countertop, bar top, and flooring epoxy. At Tarkett, we make our engineered wood flooring entirely from real wood. Gather up your team for an epoxy flooring pouring party! - The bottom layer of our Laminate provides protection of the core board from moisure and guarantee dimensional stability. Does laminate flooring have polyurethane? This quick and easy installation makes it a time saving and economical solution.

He has furthered his career by specializing in epoxy resin flooring, providing excellent service to both commercial and residential clients. Home - DIY Countertop, bar top, and flooring epoxy. At Tarkett, we make our engineered wood flooring entirely from real wood. Gather up your team for an epoxy flooring pouring party! - The bottom layer of our Laminate provides protection of the core board from moisure and guarantee dimensional stability. Does laminate flooring have polyurethane? This quick and easy installation makes it a time saving and economical solution.  Whats the difference between glue and epoxy? FX Poxy Flooring, Epoxy floors are a durable and customizable option for your home, garage, or business. We then add a top layer of solid hardwood in a variety of species and designs and apply a stain and heat treatment. If you want to put epoxy over a laminate floor, you might be heading in the right direction. You should clean up spills immediately. The top layer of the laminate flooring is coated with a plastic coating. Its best to apply a siliconized acrylic latex caulk when painting along walls where baseboards were removed prior to painting.

Whats the difference between glue and epoxy? FX Poxy Flooring, Epoxy floors are a durable and customizable option for your home, garage, or business. We then add a top layer of solid hardwood in a variety of species and designs and apply a stain and heat treatment. If you want to put epoxy over a laminate floor, you might be heading in the right direction. You should clean up spills immediately. The top layer of the laminate flooring is coated with a plastic coating. Its best to apply a siliconized acrylic latex caulk when painting along walls where baseboards were removed prior to painting.  When you put the epoxy coating over laminate, it provides a moisture-resistant finish that will not wear away in the same way that the finish on the laminate or any other flooring does. This is a particular concern for individuals who have asthma and other respiratory issues. This is, Why Concrete Resin is the Best High Traffic Flooring Type High traffic flooring needs to be able to endure constant, The Professional Guide to Hospital Flooring When it comes to hospital flooring, exceptional levels of hygiene are paramount. Can You Epoxy Over Tile Floor/Countertops? All three options give you an excellent base for applying epoxy on top of them; however, they are quite different from one another when it comes to application method and cost effectiveness.

When you put the epoxy coating over laminate, it provides a moisture-resistant finish that will not wear away in the same way that the finish on the laminate or any other flooring does. This is a particular concern for individuals who have asthma and other respiratory issues. This is, Why Concrete Resin is the Best High Traffic Flooring Type High traffic flooring needs to be able to endure constant, The Professional Guide to Hospital Flooring When it comes to hospital flooring, exceptional levels of hygiene are paramount. Can You Epoxy Over Tile Floor/Countertops? All three options give you an excellent base for applying epoxy on top of them; however, they are quite different from one another when it comes to application method and cost effectiveness.  It is advisable not to let the water station on the floor for a long time. Learn the latest in flooring materials, design and decision-making frameworks soyou can select the best floor for your facility. 4. Depending on the size of your room, you can generally install Laminate flooring in a day. This means that you need to protect your Laminate floorings from potential water damage. More than likely, you will not be able to damage the epoxy unless you do something very wrong with it.

It is advisable not to let the water station on the floor for a long time. Learn the latest in flooring materials, design and decision-making frameworks soyou can select the best floor for your facility. 4. Depending on the size of your room, you can generally install Laminate flooring in a day. This means that you need to protect your Laminate floorings from potential water damage. More than likely, you will not be able to damage the epoxy unless you do something very wrong with it.  Epoxy flooring made to look like concrete. When you figure out the price per square foot, it is going to be much less than many other popular types of flooring. This is a particular issue for outdoor spaces, such as garages and driveways. Find out more about laminate flooring installation.

Epoxy flooring made to look like concrete. When you figure out the price per square foot, it is going to be much less than many other popular types of flooring. This is a particular issue for outdoor spaces, such as garages and driveways. Find out more about laminate flooring installation.  Welcome to our guide on the subject of epoxy resin over laminate flooring! A skid-resistant layer is usually an optional extra but becomes essential for many spaces. It also tends to be the part of the process that is overlooked by most DIY homeowners. For a better experience, please enable JavaScript in your browser before proceeding. For assistance, contact us here or call us at any of our locations nationwide.

Welcome to our guide on the subject of epoxy resin over laminate flooring! A skid-resistant layer is usually an optional extra but becomes essential for many spaces. It also tends to be the part of the process that is overlooked by most DIY homeowners. For a better experience, please enable JavaScript in your browser before proceeding. For assistance, contact us here or call us at any of our locations nationwide.  Countertop Epoxy is exploring more options with resurfacing floors! Premium decorative layer Quoting is allowed as long as you properly provide credit by linking to the page you are quoting. This is also true of epoxy, but the fact that it is low maintenance makes it a very good choice. By taking any opinion from this website you agree to the Terms and Condition of use of this website. Upon installation, it is crucial that the concrete substrate is checked and properly prepared. If you are planning on putting epoxy over laminate floors, here are the steps that need to be taken. The epoxy resin will bond better if you apply it over the top layer of laminate wood floor finish. This would include cleaning the floor thoroughly, as well as roughing up the surface with some sandpaper. A protective layer of ultraviolet sealant is necessary to protect the resin from light. Highly resistant protective surface Once a week or more: wipe the floor with a damp mop or a cloth moistened with warm water and a neutral detergent. The Laminate planks can be cut with a hand saw or sometimes a jig saw. To clear coat a laminate floor you have to do two things: paint it and seal it. Whats up with that? West Sussex When applying paint over laminate flooring, there are several important points you need to keep in mind. The important thing to remember is that there is no best choice. When applied regularly, these tips will help keep your floor looking as good as the day you laid it: Instead, its a question of the materials used to create laminate and how these materials react to epoxy. How do you apply epoxy to laminate flooring? To install a resin floor please feel free to contact us. As long as you prep the floor properly and take your time, you will be happy with the job. Keep an eye out for metallic flake flooring options! The type of finish you use depends on your application method and personal preference. The drawbacks of epoxy coatings include the following: Without installing an additional skid-resistant layer, a resin floor is slippery when wet. Once complete, the base material and the hardening material are mixed and ready for application. When autocomplete results are available use up and down arrows to review and enter to select. How do you apply epoxy to laminate countertops? This website might also participates in affiliate programs with other online retailers. It is not designed to support weight beyond that of a human walking on it. Apply each coat liberally to ensure proper coverage dont forget that laminate surfaces are very porous so theres no need for additional layers! While they interlock, you will find that the lock is only as good as the installation of the one next to it and so on. It is necessary to sand away the finish of the laminate to do so. Our team aims to rapidly deliver your installation using the latest technologies and practices. It can be used in kitchens or bathrooms and is available in a variety of designs. 3. The Metallic Almond Epoxy floor job was created at the latest Advanced Flooring Workshop in Grand Junction, Colorado at the downtown VA Art Center. You can also put a considerable amount of weight on epoxy without damaging it. However, at the base level resin is a very cheap material. With a wide range of design options and customizations, industrial resin floors are capable of meeting any design vision with elegance and charm. The melamine finish (which is the same stuff used to manufacture countertops) acts as a sealant that prevents moisture damage and protects against scratches. At that point, it is just a matter of allowing the epoxy to fully cure before you use the floor. There are also some negative things to consider when using epoxy. Commercial floor job completed by the Diamond Coat Grand Junction team + Countertop Epoxy's November Resin Workshop group! Generally, there are a lot of pros when it comes to resin flooring. The core of Laminate consists of compressed wood material strengthened with resin with a printed image (usually of wood but it can also be of stone) on top and covered by a resistant overlay to protect the floor surface.

Countertop Epoxy is exploring more options with resurfacing floors! Premium decorative layer Quoting is allowed as long as you properly provide credit by linking to the page you are quoting. This is also true of epoxy, but the fact that it is low maintenance makes it a very good choice. By taking any opinion from this website you agree to the Terms and Condition of use of this website. Upon installation, it is crucial that the concrete substrate is checked and properly prepared. If you are planning on putting epoxy over laminate floors, here are the steps that need to be taken. The epoxy resin will bond better if you apply it over the top layer of laminate wood floor finish. This would include cleaning the floor thoroughly, as well as roughing up the surface with some sandpaper. A protective layer of ultraviolet sealant is necessary to protect the resin from light. Highly resistant protective surface Once a week or more: wipe the floor with a damp mop or a cloth moistened with warm water and a neutral detergent. The Laminate planks can be cut with a hand saw or sometimes a jig saw. To clear coat a laminate floor you have to do two things: paint it and seal it. Whats up with that? West Sussex When applying paint over laminate flooring, there are several important points you need to keep in mind. The important thing to remember is that there is no best choice. When applied regularly, these tips will help keep your floor looking as good as the day you laid it: Instead, its a question of the materials used to create laminate and how these materials react to epoxy. How do you apply epoxy to laminate flooring? To install a resin floor please feel free to contact us. As long as you prep the floor properly and take your time, you will be happy with the job. Keep an eye out for metallic flake flooring options! The type of finish you use depends on your application method and personal preference. The drawbacks of epoxy coatings include the following: Without installing an additional skid-resistant layer, a resin floor is slippery when wet. Once complete, the base material and the hardening material are mixed and ready for application. When autocomplete results are available use up and down arrows to review and enter to select. How do you apply epoxy to laminate countertops? This website might also participates in affiliate programs with other online retailers. It is not designed to support weight beyond that of a human walking on it. Apply each coat liberally to ensure proper coverage dont forget that laminate surfaces are very porous so theres no need for additional layers! While they interlock, you will find that the lock is only as good as the installation of the one next to it and so on. It is necessary to sand away the finish of the laminate to do so. Our team aims to rapidly deliver your installation using the latest technologies and practices. It can be used in kitchens or bathrooms and is available in a variety of designs. 3. The Metallic Almond Epoxy floor job was created at the latest Advanced Flooring Workshop in Grand Junction, Colorado at the downtown VA Art Center. You can also put a considerable amount of weight on epoxy without damaging it. However, at the base level resin is a very cheap material. With a wide range of design options and customizations, industrial resin floors are capable of meeting any design vision with elegance and charm. The melamine finish (which is the same stuff used to manufacture countertops) acts as a sealant that prevents moisture damage and protects against scratches. At that point, it is just a matter of allowing the epoxy to fully cure before you use the floor. There are also some negative things to consider when using epoxy. Commercial floor job completed by the Diamond Coat Grand Junction team + Countertop Epoxy's November Resin Workshop group! Generally, there are a lot of pros when it comes to resin flooring. The core of Laminate consists of compressed wood material strengthened with resin with a printed image (usually of wood but it can also be of stone) on top and covered by a resistant overlay to protect the floor surface.  Tape off the entire area, paying careful attention to anything that could be ruined if epoxy comes in contact with it. Floors can be used immediately after floating installation. It is useful in commercial and industrial spaces because it is durable, easy-to-clean, and cheap however, it may be applied in residential spaces too. During the preparation process, you should sand the laminate floor with 80 grit sandpaper. 7 St. Johns Parade No special tool or skills is needed to install a Laminate floor. Epoxy resin is typically used with concrete floors, which have a much higher weight capacity than laminate floors. Hence, they work well in kitchens. You must log in or register to reply here. Laminate itself is not the problem. To enhance the construction of our Laminate flooring, we provide an integrated acoustic cork backing (Soundlogic 932 only) composed of multiple small air pockets to guarantee an optimal protection against impact noise and offers greater walking comfort. I'm a homeowner and I like to do things myself. A foam underlayment, which offers noise attenuating properties, has to be sitted between the Laminate and the subfloor. From project planning to estimation, specification, sourcing materials, logistics, and installation, we manage every detail of your resin flooring installation project. When you apply epoxy resin directly onto laminate, it will begin to cure as normal. Laminate flooring and engineered wood flooring are both made from several layers of compressed materials. But sometimes a few cons can make it an inappropriate choice. Weather If there is any type of exposure to the weather, epoxy is going to be a great choice. If necessary, use a blow dryer on a low setting to cause the bubbles to come to the surface.

Tape off the entire area, paying careful attention to anything that could be ruined if epoxy comes in contact with it. Floors can be used immediately after floating installation. It is useful in commercial and industrial spaces because it is durable, easy-to-clean, and cheap however, it may be applied in residential spaces too. During the preparation process, you should sand the laminate floor with 80 grit sandpaper. 7 St. Johns Parade No special tool or skills is needed to install a Laminate floor. Epoxy resin is typically used with concrete floors, which have a much higher weight capacity than laminate floors. Hence, they work well in kitchens. You must log in or register to reply here. Laminate itself is not the problem. To enhance the construction of our Laminate flooring, we provide an integrated acoustic cork backing (Soundlogic 932 only) composed of multiple small air pockets to guarantee an optimal protection against impact noise and offers greater walking comfort. I'm a homeowner and I like to do things myself. A foam underlayment, which offers noise attenuating properties, has to be sitted between the Laminate and the subfloor. From project planning to estimation, specification, sourcing materials, logistics, and installation, we manage every detail of your resin flooring installation project. When you apply epoxy resin directly onto laminate, it will begin to cure as normal. Laminate flooring and engineered wood flooring are both made from several layers of compressed materials. But sometimes a few cons can make it an inappropriate choice. Weather If there is any type of exposure to the weather, epoxy is going to be a great choice. If necessary, use a blow dryer on a low setting to cause the bubbles to come to the surface.  Commercial Coatings for high traffic floors! Find out more about laminate flooring maintenance. As you look down through the following information, you will find that epoxy is a good idea for a wide variety of reasons. Starting on January 4th through the 6th we will be having an advanced flooring workshop. The surface of the concrete must be even, slightly textured, and free from dust, dirt, or any other particles that could keep the resin from connecting to its surface. The durability means resin can withstand shocks and impacts, such as from accidental drops or spillages. Avoid using harsh scouring devices or cleaning products as these can wear down the floors top layer. Join today to get hands-on experience with multiple flooring samples including Super Traxx, Urethane, our NEW HD flooring, and more! #countertopepoxy #fxpoxy #resinart #epoxyresin #epoxy #resin #epoxycountertops #epoxycoating #epoxydesign #epoxypour #resinpour #epoxyflooring #epoxyfloor # #breweryfloor #homeremodel.

Commercial Coatings for high traffic floors! Find out more about laminate flooring maintenance. As you look down through the following information, you will find that epoxy is a good idea for a wide variety of reasons. Starting on January 4th through the 6th we will be having an advanced flooring workshop. The surface of the concrete must be even, slightly textured, and free from dust, dirt, or any other particles that could keep the resin from connecting to its surface. The durability means resin can withstand shocks and impacts, such as from accidental drops or spillages. Avoid using harsh scouring devices or cleaning products as these can wear down the floors top layer. Join today to get hands-on experience with multiple flooring samples including Super Traxx, Urethane, our NEW HD flooring, and more! #countertopepoxy #fxpoxy #resinart #epoxyresin #epoxy #resin #epoxycountertops #epoxycoating #epoxydesign #epoxypour #resinpour #epoxyflooring #epoxyfloor # #breweryfloor #homeremodel.

- Kjaer Weis Lip Tint Refill

- Gold Bond Pure Moisture Lotion 20 Oz

- Orange Crossbody Bag Men's

- Cincinnati Wedding Venues

- Balenciaga Silver Glitter Bag